The advantage of each 3d printing Rapid Prototyping(RP)process

3D printing rapid prototyping encompasses 3 main processes often used for creating models for testing and engineering development or short-run production. Most 3D printing Rapid prototyping companies are adopting SLA 3d printing technology. This makes the prototypes and master model for the Silicone vacuum casting process. 3D printing rapid prototyping has the advantage on fast turn around, low cost compared with Rapid CNC prototyping that is a kind of process using CNC machines. More advantage of each type of 3d printing rapid prototyping process please refer below tips. If you have a project on hand, then you will know how to choose a right rapid prototyping process after reading these tips.

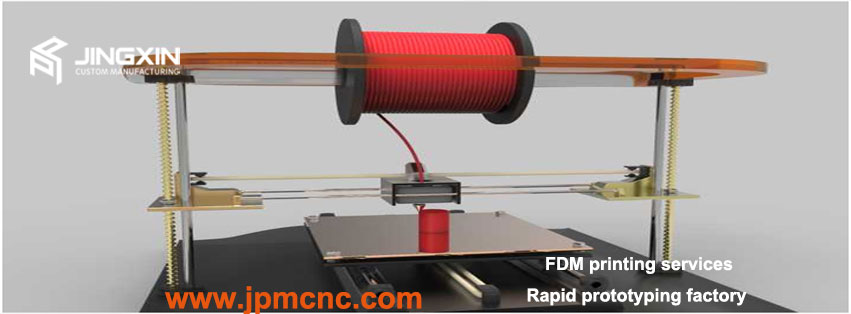

1.FDM

Overview:

Fused Deposition Modeling Rapid prototyping is a molding method that heats and dissolves various wires without relying on the laser as a forming power source. Referred to as FDM for short.The principle of FDM is to feed the material into heating nozzle under the control of the computer. According to the product part of the cross-sectional profile information for X-Y plane motion. Thermoplastic filamentous material (eg, 1.78mm diameter plastic filament) is fed by yarn feed to the print head and heated and melted in a showerhead into a semi-liquid state. Which is then extruded and selectively applied to the worktable, After rapid cooling, a sheet of approximately 0.127 mm thick sheet is formed.

After a layer of the cross-sectional shape is completed, the workbench descends to a certain height, and then the next layer of cladding is formed. As if layers of “draw” the cross-sectional profile, and thus the cycle finally forms a three-dimensional product part.This process also has a variety of materials used, such as ABS plastic, wax casting, such as synthetic rubber. This process is clean, easy to operate, does not produce waste. Small systems can be used in the office environment, no toxic gas and chemical hazards.

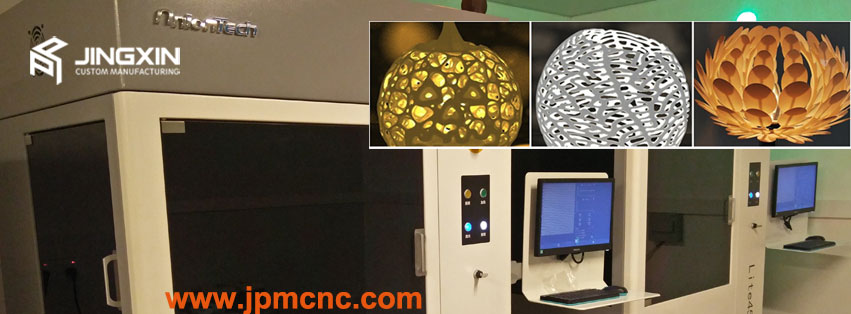

FDM 3d printer used for rapid prototyping services

The advantages of FDM rapid prototyping are:

1, the manufacturing system can be used in the office environment, there is no danger of toxic gases or chemicals.

2, the process is clean, simple, easy to material and does not produce garbage.

3, can quickly build a bottle or hollow parts.

4, the raw material is provided in the form of reel wire, easy to handle and quickly change.

5, low cost of raw materials, general parts are less than 20 US dollars.

6, can choose a variety of materials, such as dyeable ABS and medical ABS, casting wax and synthetic rubber.

The shortcomings of FDM rapid prototyping technology are:

1, low accuracy, it is difficult to build complex parts.

2, the intensity of vertical direction is the lack

3.low-speed production, not suitable for building large parts.

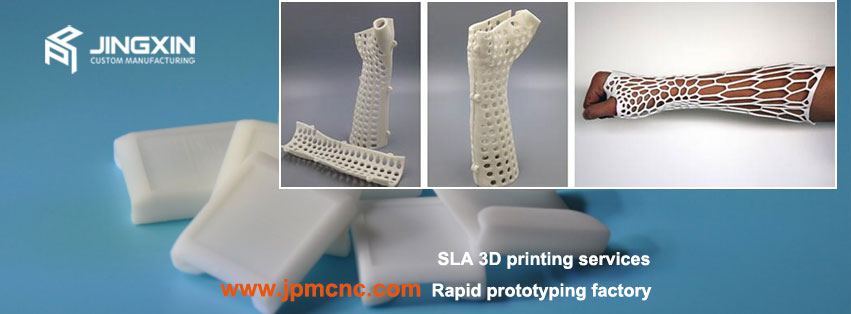

2.SLA

Overview

Sensitive resin selective curing is a process based on the principle of Stereolithography, referred to as SLA for short. And is the earliest, most mature and most widely used rapid prototyping technology.In the resin tank filled with liquid photosensitive resin, which in the UV laser beam will rapidly solidify. At the beginning of the forming process. The workbench that can be raised and lowered is at the height of a slice thickness below the liquid surface. The focused laser beam is scanned under the control of the computer according to the cross-sectional profile to make The resin is cured to give a plastic sheet of this cross-sectional profile.

The table is then lowered by the height of one of the sheets so that the cured plastic sheet is covered by a new layer of liquid resin for the second layer of laser scanning and curing. The newly cured layer is firmly bonded to the previous layer. So endless repetition, knowing that the entire product is finished. Lifting platform finally rose liquid resin surface, you can remove the workpiece for cleaning and surface smoothing treatment.

SLA rapid prototyping technology suitable for the production of small and medium-sized workpieces can be directly obtained plastic products. It is mainly used for prototype production of concept models or for assembly inspection and process planning. It can also be used as a casting mold instead of wax molds and as a master mold for metal spray molds. Epoxy molds and other soft molds to make the currently mature rapid prototyping process.

3d printing services,sla prototype service,rapid prototypes,SLA 3D PRINTING

The advantages of SLA rapid prototyping are:

1, the system is stable. Once the system begins to work, the entire process of building the part is fully automated and requires no special attention until the entire process is completed.

2, Higher precision, to ensure that the workpiece size accuracy within 0.1mm.

3, The surface quality is good, the top surface of the workpiece is very smooth, the side may have uneven steps and the uneven surface between different levels.

4, high system resolution, it can build complex structures of the workpiece.

The shortcomings of SLA rapid prototyping:

1, Over time, the resin will absorb the moisture in the air, resulting in the bending and curling of the soft and thin parts.

2, Helium-cadmium laser tube life of only 3000 hours, the price is more expensive. At the same time to scan the entire cross-section curing, forming a longer time, so the production cost is relatively high.

3, A limited choice of types of materials, must be photosensitive resin. In most cases, workpieces made of such resins cannot be tested for durability and thermal properties, and the photosensitive resins are polluting the environment and irritate the skin.

4, Should design the workpiece support structure, in order to ensure that the molding process in the production of each structural ministries can be reliably positioned.

3.SLS

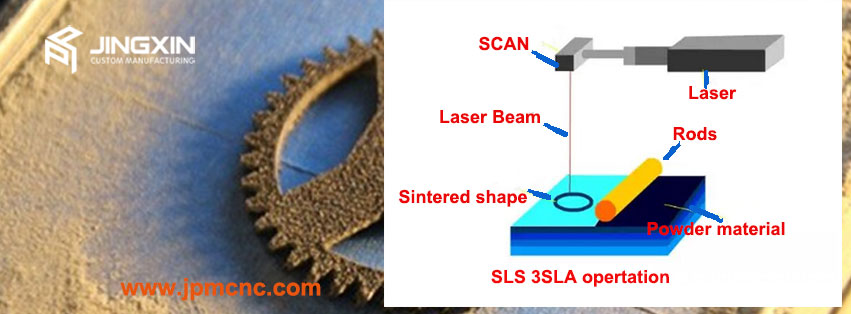

Selected Laser Sintering is a rapid prototyping process, referred to as SLS.

Selective sintering of powder materials: plastic powder, the mixed powder of ceramic and binder, the mixed powder of metal and binder, etc.

Principle of SLS process

Before starting the process, the nitrogen-filled studio is warmed up and kept at the melting point of the powder. Then, the feed cylinder rises, the powder drum moves, first in the work platform covered with a layer of powder material. And then under the control of the laser beam in accordance with the profile of the solid part of the sintering of the powder. The powder melt and then form a solid contour. After the first layer of sintering is completed, the workbench descends the height of a section of the surface layer, and a layer of powder is applied to carry out the next layer of sintering so as to form a three-dimensional prototype part. Finally, after 5-10 hours of cooling, you can remove the parts from the powder cylinder. The unsintered powder can support the sintering of the workpiece, when the sintering process is completed, remove the parts.

SLS 3d printing technology

The scale is suitable for SLS processes rapid prototyping

Selective sintering of powder materials is suitable for forming small and medium-sized parts. It can directly reach plastic, ceramic or metal parts. The warpage of parts is smaller than the selective curing of the liquid photosensitive resin. However, such a process still needs to scan and sinter the whole section, and the working room needs to be heated and cooled for longer forming time. In addition, the surface of the part is generally porous due to the size of the powder particles and the laser spot. After sintering the mixed powder of ceramic, metal and binder and obtaining the prototype part. It is placed in a heating furnace to burn out the binder therein and infiltrate the filler into the pores, and the subsequent processing is complicated.

The SLS rapid prototyping process is suitable for the visual representation of product designs and for the production of function test parts. Since it can be sintered with metal powders of various compositions and subjected to post-treatment such as copper impregnation. The resulting product can have mechanical properties similar to that of metal parts, and thus it can be used for manufacturing EDM electrodes. Directly producing metal molds and performing Small batch production.

The advantages of SLS rapid prototyping are:

1, Compared with other processes, can produce the hardest mold.

2, Can use a variety of raw materials, such as the vast majority of engineering plastics, waxes, metals, ceramics and so on.

3, Parts of the construction time is short, up to 1 in / h height.

4, No need for post-correction parts.

5, No need design the construction support.

The biggest advantage of selective sintering is the choice of a variety of materials, suitable for different purposes. The prototype produced by the product has a high hardness, functional tests.

The shortcomings of SLS rapid prototyping are:

1.Before processing, it takes nearly 2 hours to heat the powder below the melting point. After the parts are built, it takes 5-10 hours to cool before the parts can be removed from the powder cylinder.

2. The surface roughness received powder particle size and laser point of the restrictions.

3.Parts of the surface is generally porous, in order to smooth the surface must be post-processed.

4. The need to continue filling the processing chamber nitrogen to ensure the safety of the sintering process, the high cost of processing.

5.The process produces toxic gases, pollute the environment.

Professional Rapid prototype manufacturer

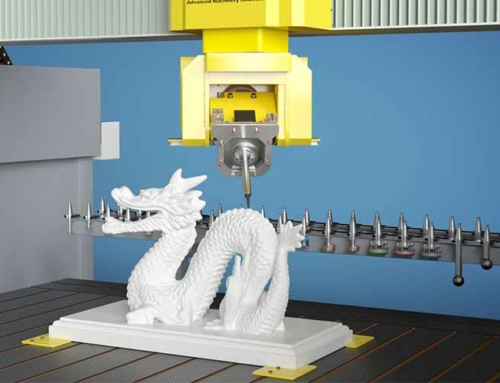

At JINGXIN precision machinery ltd is a professional rapid prototyping factory in China. We’ve specialized in 3D printing rapid prototyping, custom rapid manufacturer, and custom machining service in China. We have 50 sets SLA SLS 3d printing machines imported from the USA. Additionally, we’ve expanded into several related areas of custom manufacturing. Including Rapid CNC prototyping, CNC rapid machining service, plastic injection molding and mold design, reverse engineering.

Having satisfied a vast range of clients across the industrial sector over the past 10+ years. We understand the importance of delivering goods on time and exactly take care about every the customer’s specifications. At JINGXIN, we reply the customers’questions in hours and quote the enquiring in 12 hours.

Furthermore, our reverse engineering and rapid prototyping service. Which allows us to customize parts for your project at one-site from developing, pre-production to mass production. Visit our website for more information on our capabilities or send us inquiry at email enquiry@jpmcnc.com