CNC machining services

CNC machining services

CNC machining services are efficient in terms of both time and cost.

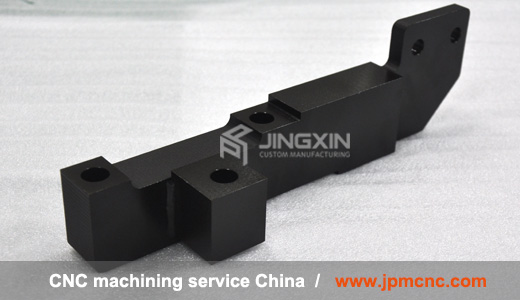

JINGXIN is a custom CNC machining parts vendor in China,trusted by some brand company, as an approved contracting custom CNC machined components vendor in China since 2014.

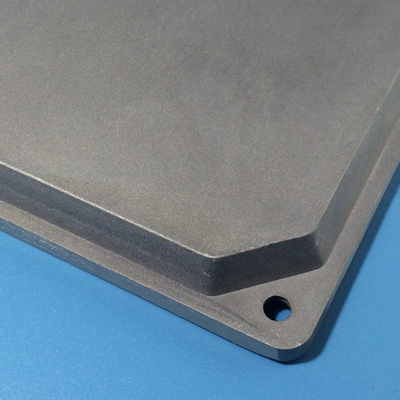

At JINGXIN precision machinery Ltd,offers CNC milling services including CNC milling services and CNC turning services,we work with various kind of material such as plastic and metal parts for Short-run production or 10000+ production. Applications include parts for Auto parts,medical, Aerospace CNC machining with Aerospace material industry.etc.

Tolerance range of precise CNC machined parts from +/- 0.005mm~0.01mm;

The standard Lead time within 1-2 weeks. Rush Service Available

Get a project review and CNC machining Quote (Mr. Sammy:enquiry@jpmcnc.com)

Industrial Served

| Automotive CNC Milling and turning | Heavy Equipment |

| Electronic components made by CNC milling | Trucking accessories production CNC machining |

| Medical parts made by 5 Axis CNC machine | Music Equipment |

| Semiconductor prototype CNC machining | Custom CNC machining Mining parts |

| Signage | Security products Online CNC machining |

| Military accurate CNC machining services | Construction CNC machining manufacturer |

| Industrial contract CNC machining services | Architectural CNC machined parts |

Our Advantages

Quick turn & Service

Quick feedback in 24 hours.Case by case followed via One-on-one service.

Fast Lead time

JINGXIN skilled machinists produce high-quality parts as little as 3-6 working days

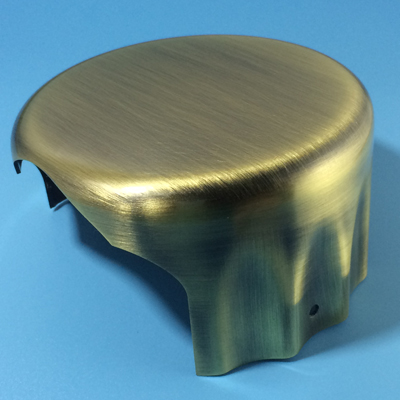

Custom finishes

Select from a variety of finishes and surface treatment or up on request.

High precision

tolerances ranging from +/-0.01mm – 0.05mm, or up on customers’ specs.

Value Added service

Product design, Assembly, Packaging, Programming

Custom CNC Machining services Capabilities

CNC machining service is a manufacturing process where pre-programmed computer software controls the movement of tools and machinery in a factory or workshop. This type of machining is used to create parts or components with high precision and accuracy, and it is commonly used in a variety of industries, including aerospace, automotive, medical devices, electronics, and more.

The application of CNC machining services can vary depending on the industry and the specific needs of the project. Some common applications include:

- Prototyping: CNC machining can be used to create accurate prototypes of a product or component before going into mass production.

- Production: CNC machining can be used for high-volume production runs to produce consistent and high-quality parts or components.

- Customization: By CNC machining, create customized parts or components for specific applications or customer requirements.

- Repairs and Maintenance: CNC machining can be used to repair or replace worn or damaged parts or components.

- Research and Development: CNC machining can be used in research and development to create new products or to improve existing ones.

Overall, CNC machining services are a versatile and widely used manufacturing process that can be applied to a variety of industries and applications.

A Full Range of Services

| CNC Milling | CNC Turning |

|---|---|

| High speed drilling | Tapping |

| Boring | Slotting |

| Reaming | Rotary Broaching |

Value Added Services

| Lasing cutting service | Laser Marking |

|---|---|

| Laser Engraving for Anodizing CNC machined aluminum parts | Welding & Forming for sheet metal fabrication |

| Debrring to remove all sharp edges and burrs | Assembly & Packaging |

| Product design & assistance | Programming |

Multi-Axis (4 & 5 Axis) CNC machine center and Vertical Machining Centers (VMC) Maximum machining size

- Maximum Table size 1200mmLx1000mmW

- Spindle speeds up to 12,000 RPM

- Z heights to 508mm

| No. | Model | Brand | sets | Maximum machining parts size | Year |

|---|---|---|---|---|---|

| 01 | 3 Axis CNC machine center | Brother(Taiwan) | 20 | 1200mmL*1000mmW*500mmH | 2014 |

| 02 | 4Axis CNC machine center | HASS (USA) | 5 | 1000mmL*1000mmW*500mmH | 2015 |

| 03 | 5 Axis CNC machine center | Brother(Taiwan) | 3 | 800mmL*800mmW*400mmH | 2015 |

| 04 | CNC Lath | BAOJI(CHINA) | 10 | 400mm Diameter | 2014 |

CNC machining services workmanship VS Traditional

| Advantage | CNC machining services | VS | Traditional Manufacturing |

|---|---|---|---|

| Lead times | Fast in 3-7 days for 100-1000 pcs production | Slow | |

| Production efficiency | High speed machining equal to save cost | Low | |

| 3D complex parts | 4& 5 Axis CNC machining | simple parts | |

| Operation Control | Computer Numerical Control | Depends on the skilled machinist | |

| Surface | high, smooth and bur free | N/A | |

| Quality assurance | One stop site for Tiny or large parts with complex design | one type equipment Only for a single process |

Available Materials Listing

♦General Purpose material for CNC machining services, Raw material forms can be sheet/bar stick/tubing/plate

♦All materials comply with RoHS (Restriction Of Hazardous Substances), the Material certificate and X-ray inspection report are available.

Non-Metal & Plastics bar /sheet

| No. | Non-metal Material for CNC machining sevices parts |

|---|---|

| 01 | ABS |

| 02 | PC (Polycarbonate) |

| 03 | Delrin |

| 04 | PEEK |

| 05 | POM |

| 06 | PMMA (Acrylic) |

| 07 | Bakelite |

| 08 | PVC |

| 09 | Teflon |

| 10 | Other special plastic |

Metals

| No. | Type | Grade (made in China Or Germany, Japan |

|---|---|---|

| 01 | Aluminum Alloy | EN AW 2007/2017A 5052 /5754/6061/ 6063 / 7075 ,.etc. |

| 02 | Brass&Copper | 3602 / H59 / H62 / C3600/C38500/,.etc. |

| 03 | Stainless steel | SS 301, SS303/SS304,SS316/SS316L/SS400,SS430,etc |

| 04 | Carbon Steel | A2,D2,S136,Q235,GB#20,GB#45.etc |

| 05 | Titanium Alloy | |

| 06 | Magnesium alloy | |

| 07 | Zinc alloy | |

| 08 | Tungsten Carbide | YG8,YG10 |

| 09 | Other | Up on Customer’s requests |

Available finishes & surface treatment

JINGXIN Features

- 100+ hours resistance to salt spray

- Thin coating

- Advanced coating adhesive techniques

- Environmentally friendly

- JINGXIN’s coating is completely chromium free and RoHS compliant

Project Service Guide

-

Enquiry

Design Source Files(STL、STP etc); Order Quantity; Tolerance Range; Surface Treatment Requirements; Purpose

-

Project Review & Quote

Sign NDA(non-disclose-aggrement) if need. Project Review By Engineers Follow Up Project all details; Make Quotation for client

-

Biz Terms

Shipping method & documents; Term of Payment; Packaging Details; Delivery Date,etc.

-

Project Execution

Production Plan; Workflow & Process Control; Monitoring in whole procedure. Feedback to Client continually.

-

100% QA before Shipping

All Functions Testing; Surface Testing; Go Through All Project Details; Packing Testing; Testing & QA Report.