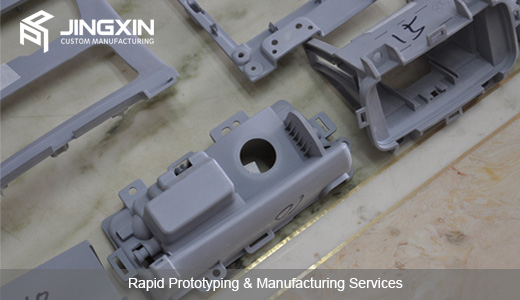

Rapid Prototyping and Rapid manufacturing services

JINGXIN® precision machinery Ltd., has 12 years experience of rapid prototyping, Creating models, patterns, and short run production. JINGXIN® is trusted by BMW(Germany), VOLVO (Sweden), NFL(USA), etc.

JINGXIN® precision machinery Ltd., has 12 years experience of rapid prototyping, Creating models, patterns, and short run production. JINGXIN® is trusted by BMW(Germany), VOLVO (Sweden), NFL(USA), etc.

we have done 1000+ cases and its Applications include parts for research and development, pre-production, qualification testing, and trade show samples. Tolerance range from +/-0.01~+/-0.05mm or up on clients specs.Welcome to Contact our Project manager(Mr Sammy : sammy@jpmcnc.com) directly for your project.

Our RP Advantages

Quick turn & Service

Quick feedback in 24 hours.Case by case followed via One-on-one service.

Fast Lead time

JINGXIN skilled machinists produce high-quality parts as little as 3-6 working days

Custom finishes

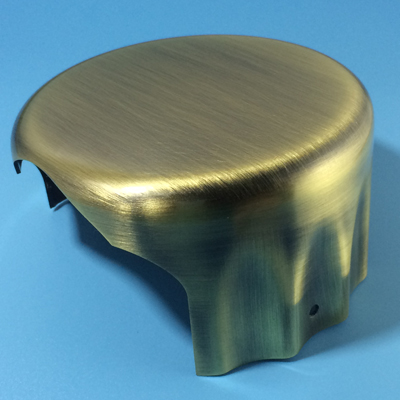

Select from a variety of finishes and surface treatment or up on request.

High precision

tolerances ranging from +/-0.01mm – 0.05mm, or up on customers’ specs.

Value Added service

Product design, Assembly, Packaging, Programming

Choose the reasonable RP solution

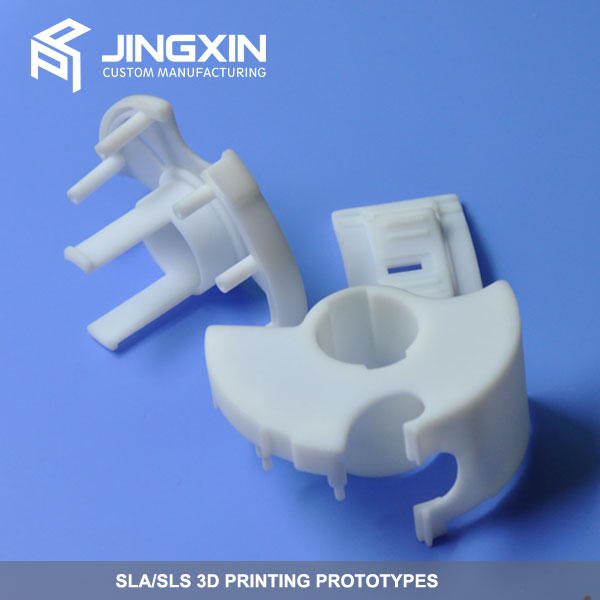

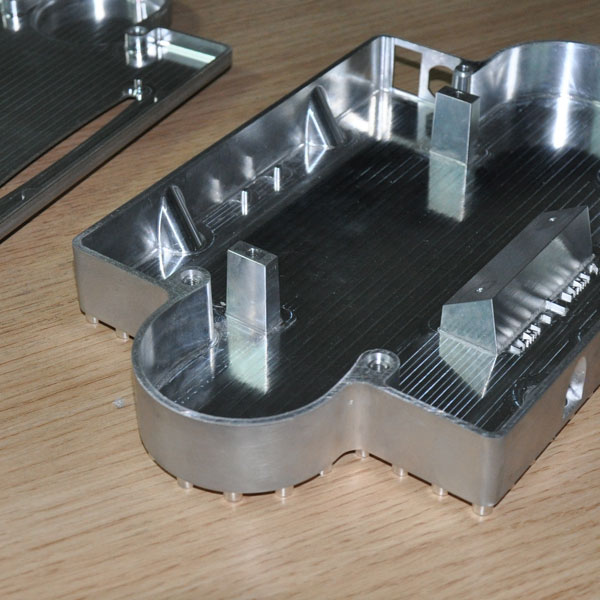

| SLA /SLS 3d printing Learn more | CNC machining Learn More | Vacuum Casting Learn more | |

|---|---|---|---|

| Totalerance Range | +/-0.1-0.2mm | +/-0.01-0.1mm | +/-0.1-0.2mm |

| Machining cablity | 850mmLx850mmWx350mmH | 1200mmLx1200mmWx800mmH | 1200mmLx1200mmWx800mmH |

| Lead times | 1-3 working days | 3-6 working days | 3-6 working days |

| Cost | Low | High | Middle |

| Application | Engineering Evaluation/New project delvepoment /out-looking /exhibition | Engineering Evaluation/New project delvepoment /function testing,Customized, | New project delvepoment /function testing,Customized |

| Advantage | Fast lead time | High precision and fast turnaround | Short run production without expensive hard tooling |

Available Materials Listing

General Purpose material for Rapid prototyping; Raw material forms can be sheet/bar stick/tubing/plate

Available Plastic Material Listing

| No. | Material |

|---|---|

| 01 | ABS |

| 02 | PC |

| 03 | PA66 |

| 04 | PEEK |

| 05 | POM |

| 06 | PMMA |

| 07 | Bakelite |

| 08 | Other special plastic |

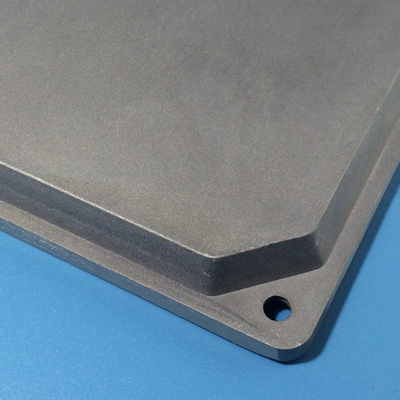

Available Metal Material Listing

| No. | Type | Grade |

|---|---|---|

| 01 | Aluminum Alloy | 5052 /6061/ 6063 / 2017 / 7075 ,.etc. |

| 02 | Brass&Copper | 3602 / H59 / H62 / C3600/C38500/,.etc. |

| 03 | Stainless steel | SS 301,SS304,SS316,SS400,SS430,etc |

| 04 | Steel | A2,Q235,20#,45#.etc |

| 05 | Titanium Alloy | |

| 06 | Magnesium alloy | |

| 07 | Zinc alloy | |

| 08 | Other | Up on Customer’s requests |

Project Service Guide

-

Enquiry

Design Source Files(STL、STP etc); Order Quantity; Tolerance Range; Surface Treatment Requirements; Purpose

-

Project Review & Quote

Sign NDA(non-disclose-aggrement) if need. Project Review By Engineers Follow Up Project all details; Make Quotation for client

-

Biz Terms

Shipping method & documents; Term of Payment; Packaging Details; Delivery Date,etc.

-

Project Execution

Production Plan; Workflow & Process Control; Monitoring in whole procedure. Feedback to Client continually.

-

100% QA before Shipping

All Functions Testing; Surface Testing; Go Through All Project Details; Packing Testing; Testing & QA Report.