It is important for a designer to Choose a right rapid prototyping companies to serve their new developing project. with newly designed products, the designer needs to go through testing, validation, and verification before putting it into market. So the Rapid prototyping must be created to see if the design works properly and checking the construction if it is reasonable for mass production or testing its function as you expected. How that is achieved ? what makes the difference in? how long it takes to get development done and the product to market. Where can I find the best rapid prototyping companies?

The Right Rapid Prototyping Companies Of Selection

Rapid Prototyping is the best solution for new products developments with short time consuming and no expensive tooling cost, especially for the complex, multi-functions parts. In the past, all these components would require a full set of custom tooling or hand-made, tooling is hugely time-consuming (several weeks to as much as six months) and expensive (would be $8000.00~20000.00). Now, at JINGXIN@ precision machinery Ltd,as specialized rapid prototyping companies, we offer a full range of rapid prototyping service which could include SLA rapid prototyping, Rapid CNC prototyping, Vacuum casting(Urethane Casting).etc

The following factors to consider before choosing

Before choosing a right prototyping method for your projects, JINGXIN@ experts advise the following factors to consider

1) How many parts do you need?

2) What types of material characteristics do you require for the prototype and, ultimately, the product?

3) What is your budget?

4) When do you need the parts? Whether you need them now or in a few weeks will help determine which process to use.

5) In what stage of product development are you?

6) Will you likely need to make modifications? If so, then you might want to start off with the lower risk of 3D printing.

7) What is the life expectancy of this product?

8) Are you familiar with the options? There is also investment casting, and that can also serve a purpose. You must weigh out your options.

9)Do you need the parts with the fine surface , or should be surface treatment like painting, coating plating?

Which method to use?

| SLA /SLS 3d printing Learn more | CNC machining Learn More | Vacuum Casting Learn more | |

|---|---|---|---|

| Totalerance Range | +/-0.1-0.2mm | +/-0.01-0.1mm | +/-0.1-0.2mm |

| Machining cablity | 850mmLx850mmWx350mmH | 1200mmLx1200mmWx800mmH | 1200mmLx1200mmWx800mmH |

| Lead times | 1-3 working days | 3-6 working days | 3-6 working days |

| Cost | Low | High | Middle |

| Application | Engineering Evaluation/New project delvepoment /out-looking /exhibition | Engineering Evaluation/New project delvepoment /function testing,Customized, | New project delvepoment /function testing,Customized |

| Advantage | Fast lead time | High precision and fast turnaround | Short run production without expensive hard tooling |

3D PRINTING & ADDITIVE MANUFACTURING

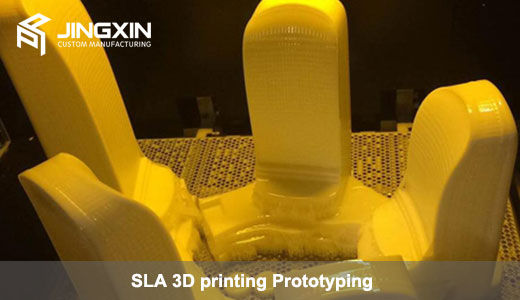

3D printing is evolving rapidly, with new processes and materials appearing, it is great for creating very small parts and complex geometries parts ,Most prototyping companies delivery the rapid prototypes in 6-10 days. At JINGXIN, as a leading rapid prototyping company, our lead time is within 2-5 working days.

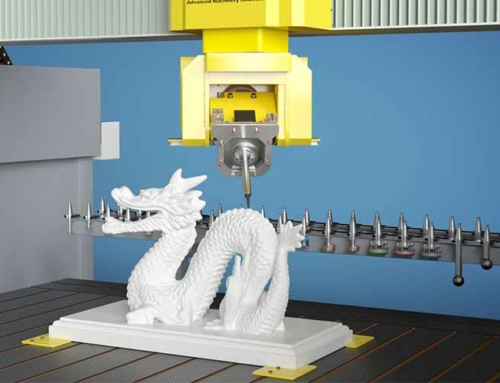

SLA 3D printing has the greatest choice of materials and the smoothest surface finish. It utilizes a resin-like material, so products made this way will not be long-lasting like a thermos-plastic, but there are several choices of feedstock strengths, transparencies and temperature resistance.

The finishing options, which can be painted the color what you need like the actual product will appear.

Learn more what is 3d printing and how does 3d printer work or contact JINGXIN experts directly

CNC (COMPUTER NUMERICALLY CONTROLLED) MACHINING

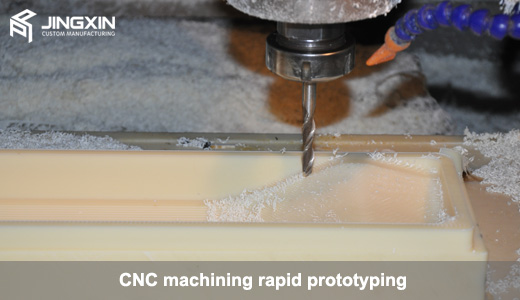

According to JINGXIN prototyping companies’ expert’s suggestions, when comparing 3D printing to Rapid CNC prototyping, the main factor for choice is how many prototyping parts you need for testing, the lead time and the costs. Parts can be done in plastics and metals.Precision CNC machine can work with thermoplastic materials as well as hard and soft metals such as aluminum, copper, brass and stainless steel. Rapid machining services can be used for one-off prototypes, end-use functional parts and jigs, and fixtures. CNC machining is generally faster than 3D printing and is better for larger volumes of parts.

CNC machined plastic rapid prototyping parts or metal parts can be very precise; CNC mills can make thousands of perfect copies of an object very quickly. CAD programs can be used to design the part and that design can be seamlessly used to program the CNC mill to create the part at relatively low cost. Jingxin@ has CNC machines of their own, more about JINGXIN @ equipment list please refer to our website www.jpmcnc.com.

When deciding between CNC and 3D printing, also consider the part geometry and the number of products needed to determine which is more economical.

Vacuum casting or rapid tooling plastic injection molding

With vacuum casting and injection molding, many parts can be created and produced at the same time quickly, with low labor costs and a high repeat tolerance. Generally, there is little finishing required as parts usually have a finished look upon ejection.

This is a good process for prototyping, bridge tooling, and low-volume product. There are hundreds of colors and engineering-grade plastics available for injection molding.

If you want to find a prototyping companies in China to help you finish a prototype for your new project please contact JINGXIN experts to help you choose the best solutions.

What Can we help you do next?

∇ Get more information about Rapid prototyping

→Case study-Find out what we have done.