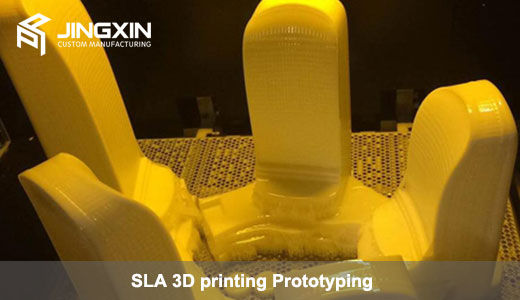

SLA/SLS 3D printing services

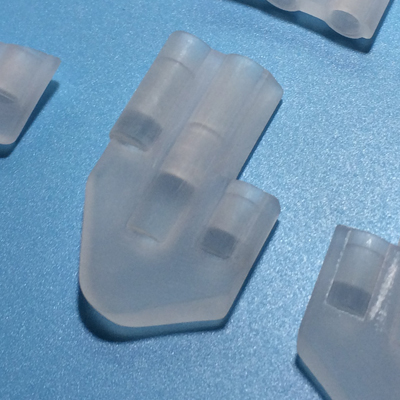

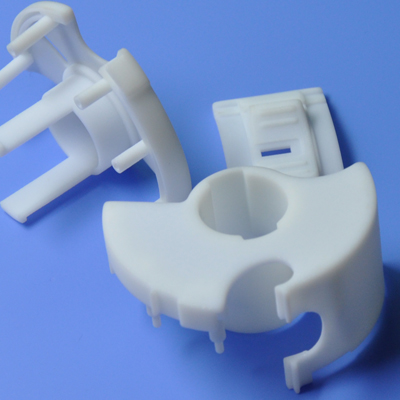

SLA 3D printing process is often chosen for creating prototypes and models because it produces clean, crisp forms with layering that is difficult to see or feel. also, no investing on tooling and the Fast lead time within 1-2 working days, the finish will be the same as injection molded. its Applications include parts for research and development, pre-production, qualification testing, and trade show samples. Tolerance range from +/-0.1~+/-0.2mm or up on clients specs.

SLA 3D printing process is often chosen for creating prototypes and models because it produces clean, crisp forms with layering that is difficult to see or feel. also, no investing on tooling and the Fast lead time within 1-2 working days, the finish will be the same as injection molded. its Applications include parts for research and development, pre-production, qualification testing, and trade show samples. Tolerance range from +/-0.1~+/-0.2mm or up on clients specs.

Welcome to Contact our Project manager(Mr Sammy : sammy@jpmcnc.com) directly for your project.

To learn more and get an overview of 3 major 3d printing technology and process.

Our SLA 3d printing Advantages

Quick turn & Service

Quick feedback in 24 hours.Case by case followed via One-on-one service.

Fast Lead time

JINGXIN skilled machinists produce high-quality parts as little as 1-3working days

Custom finishes

Select from a variety of finishes and surface treatment or up on request.

High precision

Tolerances ranging from +/-0.1mm – 0.2mm, or up on customers’ specs.

Value Added service

Product design, Assembly, Packaging, Programming

SLA 3D printing VS Traditional process

Are you ready to get a prototype made by 3d printing to check your design for a new developing project? The following tips you may concern:

| Advantage | SLA/SLS 3D printing prototyping | Traditional rapid prototyping | |

|---|---|---|---|

| Lead time | 1-2 days | VS | 3-5 days |

| Cost | Low | 10+ times SLA cost | |

| Part design | Wall Thickness can be 0.2~0.3 mm | Wall Thickness at last 0.5~1mm | |

| Raw Material | Photopolymer | All kinds of plastic and metal parts | |

| Precision | 0.1~0.2mm | 0.02~0.1mm | |

| Physical characteristics | Less Strength and rigid | Better than SLA/SLS prototypes | |

| Surface & finish | Various finish can be made on the parts | Various finish can be made on the parts | |

| Application | Outlooking checking and design evaluate | Assembly checking and function testing |

| SLA /SLS 3d printing Learn more | CNC machining Learn More | Vacuum Casting Learn more | |

|---|---|---|---|

| Totalerance Range | +/-0.1-0.2mm | +/-0.01-0.1mm | +/-0.1-0.2mm |

| Machining cablity | 850mmLx850mmWx350mmH | 1200mmLx1200mmWx800mmH | 1200mmLx1200mmWx800mmH |

| Lead times | 1-3 working days | 3-6 working days | 3-6 working days |

| Cost | Low | High | Middle |

| Application | Engineering Evaluation/New project delvepoment /out-looking /exhibition | Engineering Evaluation/New project delvepoment /function testing,Customized, | New project delvepoment /function testing,Customized |

| Advantage | Fast lead time | High precision and fast turnaround | Short run production without expensive hard tooling |

Advanced SLA 3D printing Equipment

| No. | Type | Brand | Set | Maximum manufacturing size |

|---|---|---|---|---|

| 01 | SLA | Unitech 450 | 10 | 800mmL*800mmW*400mmH |

| 02 | SLS | Stratasys | 5 | 500mmL*500mmW*300mmH |

Available SLA 3D printing Materials Listing

A special type of liquid plastic (photopolymer) is used that reacts with ultraviolet (UV) light to form a solid.

More details please refer to the material Technical data sheet

| No. | Material | Process | Data sheet Download |

|---|---|---|---|

| 01 | SOMOS 14120 | SLA | Technical data sheet SOMOS 14120 |

| 02 | SOMOS 11122 | SLA | Technical data sheet SOMOS 11122 |

| 03 | EOS PA2200 | SLS | Technical data sheet EOS PA2200 |

Project Service Guide

-

Enquiry

Design Source Files(STL、STP etc); Order Quantity; Tolerance Range; Surface Treatment Requirements; Purpose

-

Project Review & Quote

Sign NDA(non-disclose-aggrement) if need. Project Review By Engineers Follow Up Project all details; Make Quotation for client

-

Biz Terms

Shipping method & documents; Term of Payment; Packaging Details; Delivery Date,etc.

-

Project Execution

Production Plan; Workflow & Process Control; Monitoring in whole procedure. Feedback to Client continually.

-

100% QA before Shipping

All Functions Testing; Surface Testing; Go Through All Project Details; Packing Testing; Testing & QA Report.