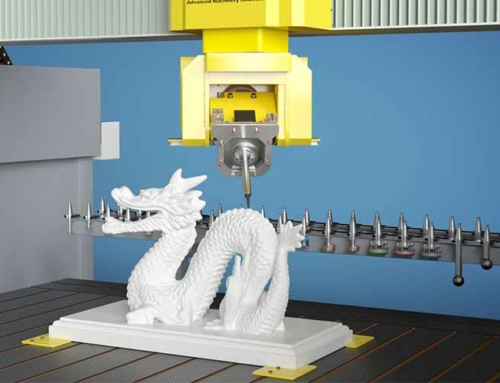

Top 8 Surface Finishes for CNC machined metal parts

For surface finishes for cnc machined metal parts. While the tool marks left on CNC machined metal parts and components made by another manufacturing process. In many cases, some additional post-processing may be desired or even required. There are a variety of finishes that one can use to add functionality or aesthetic appeal to parts. However we JINGXIN list some very common finishing methods and expect that will help you decide which of them may be a good choice for your machined parts. The follow lists top 8 surface finishes for cnc machined metal parts.

When selecting surface finishes for CNC machined parts, consider: material compatibility, functional requirements and aesthetic goals.

CNC Machined Parts Finishing, Tips of Tips of Surface Finishing For CNC Machined Parts

-

Anodizing

Anodizing is mainly applied to aluminum parts,as one of special method for surface finish for cnc machined parts. It is the use of electrochemical principles to generate a layer of Al2O3 (alumina) film on the surface of aluminum and aluminum alloys parts. This layer of oxide film has special properties such as protection, decoration, insulation and abrasion resistance.

- Single color or double color on one part, any kinds color or customized color except white.

- Additional process before anodizing to make the parts different looking. Glossy by polishing; Sandblasting, Brushing.

- The additional process after anodizing, Lasing engraving for Model notes; marks; company logo; or other design, this will make the parts looking like unique.

- Nickel-free sealing, to meet the requirements of countries such as Europe and the United States without nickel.

- Enhance the surface hardness

Anodizing For CNC Machined Metal Parts

2. Electroplating for metal parts

Electroplating is a technique in which a metal film is attached to the surface of a metal by electrolysis to prevent corrosion, improve abrasion resistance, conductivity, light reflection, and enhance appearance. There are most popular electroplating is Nickel plating, Zinc plating, Chrome plating, Brass plating, .etc.

- Plating gloss, high-quality metal appearance;

- Competitive cost then PVD.

Electroplating For CNC Machined Parts

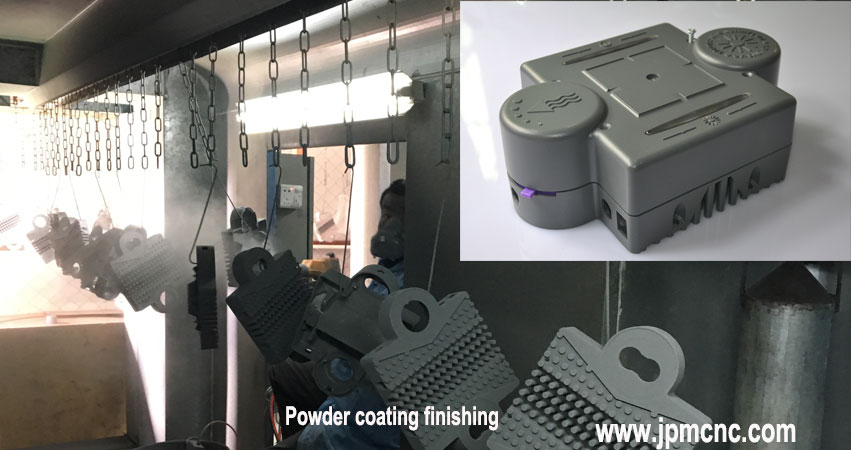

3. Powder coating

Powder spraying uses powder spraying equipment (electrostatic spraying machine) to spray the powder coating on the surface of the workpiece. Under the electrostatic action, the powder will be uniformly adsorbed on the surface of the workpiece to form a powder coating. the powder coating is subjected to high temperature drying The baking leveling cures to a final coating with various effects (different types of effects for powder coatings).

- Rich colors, high gloss or matte optional.

- lower cost, suitable for construction furniture products and heat sink shell; outdoor or indoor used CNC machined parts, sheet metal stamping or bending housing.

- high utilization, 100% utilization, environmental protection.

- Strong ability to shield defects, such as the parts made of aluminum & Zinc alloy die casting parts like lighting fixtures.

CNC Machined Parts Finishing, Tips of Tips of Surface Finishing For CNC Machined Parts

4. Spray painting

Spray painting is a painting technique where a device sprays a coating (paint, ink, varnish, etc.) through the air onto a surface.

CNC Machined Parts Finishing, Tips of Tips of Surface Finishing For CNC Machined Parts

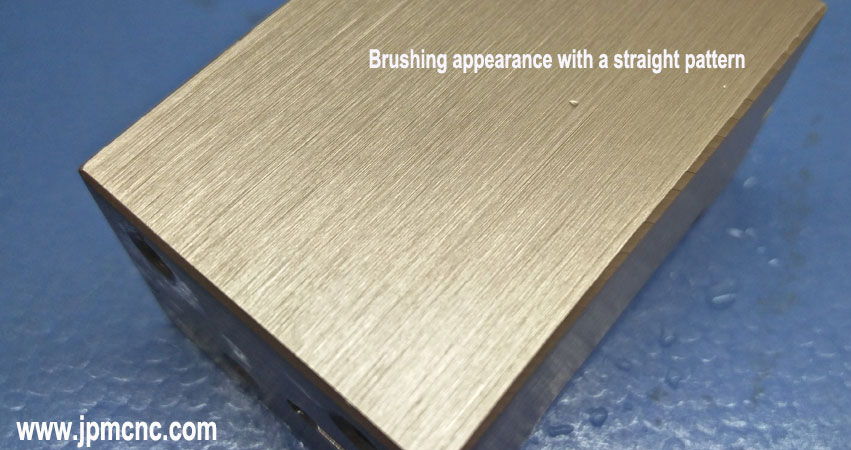

5. Brushing

Brushing finishing process is a kind of surface treatment method that forms a line pattern on the surface of the workpiece by grinding product and plays a decorative effect. According to the different lines after brushing can be divided into straight-line brushing, chaotic pattern brushing, corrugated, swirling pattern.

The brushing process gives the metal surface a non-mirror-like metallic luster, while the brushing process also eliminates the tiny defect on the metal surface.

Brushing is mostly used for stainless steel parts or before anodizing aluminum parts, even for electroplating parts as post-process after plating.

CNC Machined Parts Finishing, Tips of Tips of Surface Finishing For CNC Machined Part

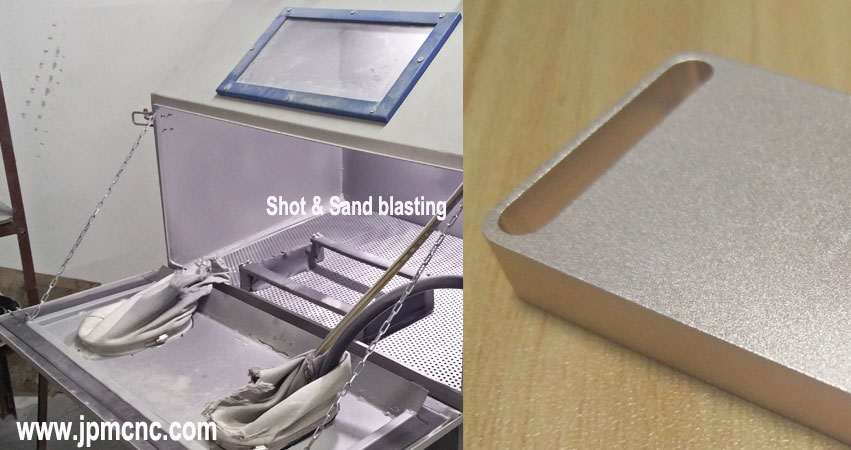

6. Shot Blasting

Sandblasting and bead blasting

Sandblasting and bead blasting is powered by compressed air to form a high-speed jet beam to spray the material at high speed onto the surface of the workpiece. It is processed so that the appearance or shape of the external surface of the workpiece surface changes, and a certain cleanliness and different roughness are obtained.

- To achieve different reflective or matte.

- It can clean the tiny burrs on the surface of the workpiece and make the surface of the workpiece smooth. Eliminating the danger of burrs and improving the grade of the workpiece.

3, clear the residue left before the pre-treatment, improve the workpiece finish. The workpiece can expose a uniform metal color so that the appearance of the workpiece looks more beautiful

CNC Machined Parts Finishing, Tips of Tips of Surface Finishing For CNC Machined Parts

7. Polishing

Polishing is the use of flexible polishing tools and abrasive particles or other polishing media to modify the surface of the workpiece. For different polishing processes: rough polishing (basic polishing process), medium polishing (finishing process) and polishing (glazing process). The use of a suitable polishing wheel can achieve the best polishing effect while improving polishing efficiency. Improve the dimensional accuracy or geometry accuracy of the workpiece to obtain a smooth surface or mirror gloss while eliminating gloss.

CNC Machined Parts Finishing, Tips of Tips of Surface Finishing For CNC Machined Parts

8. Etching

Etching, also known as photochemical etching, refers to the removal of the protective film of the area to be etched by exposure to the plate. Exposure to chemical solutions during etching, to achieve dissolution corrosion effect, the formation of uneven or hollow forming effect.

CNC Machined Parts Finishing, Tips of Tips of Surface Finishing For CNC Machined Parts

Of course, Not only are many of the above metal finishes. But also there are various other finishing for CNC machined components or other metal parts, as well many can also be used in combination. For example, a CNC machined aluminum part could be sand & bead blasted or brushed with a straight line to give it the desired surface finish. And then anodized to add color and protection from scratching and corrosion. However, because each finish requires careful attention to detail and will spend more time. Therefore, the cost of parts would be subjected to the desired finishes. Even it will cost double than black parts sometimes.

If you have a new project such as customized CNC machining parts or sheet metal stamping parts, Welcome to contact JINGXIN’s project manager (Mr. Sammy: enquiry@jpmcnc.com) for more details of metal parts finishes, our team would glad to work out a best finishes solutions options basing on your requirements.