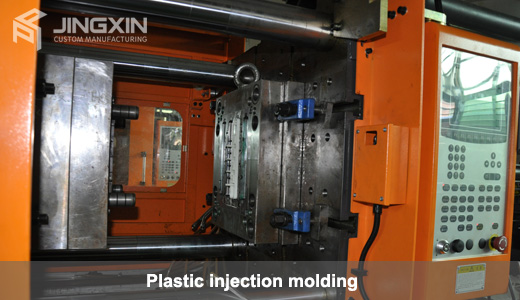

INJECTION MOLD& MOLDING

Plastic injection mold & molding is the most commonly used for plastic parts fabrication and efficient in terms of both time and cost,

JINGXIN® Precision Machinary Ltd is the factory of Plastic Injection mold making, custom molds and parts in China.more than 20 years and 100+ skilled engineer and machinist.we offer export mold & tooling , and Injection molding services with many kinds of plastic material. Applications include parts for Auto parts, medical, industry. Typical tolerance range from +/- 0.05mm-0.1mm.

Welcome to Contact our Project manager(Mr. Sammy : sammy@jpmcnc.com) directly for your project.

Advantages in Mold & Molding

Quick turn & Service

Quick feedback in 24 hours.Case by case followed via One-on-one service.

Mold making in House

JINGXIN’s Advanced mold making systems and Mold making in House, Quality control

Quality Control & Guarantee

ISO Certificated factory

High precision

tolerances ranging from +/-0.05mm – 0.1mm, or up on customers’ specs.

Value Added service

Product design, Assembly, Packaging, Programming

Capabilities in Mold & Molding

A Full Range of Services

| Insert Molding | Over Molding |

|---|---|

| Two or three colors Molding | Internal / External Threads |

| Custom colors | Simple or Complex Parts |

Value Added Services

| Lasing Marking | UV glossy painting |

|---|---|

| Laser Engraving | Assembly & Packaging |

| Product design & assistance | Unlimited Part Quantities |

Equipment list for mold & molding

Plastic injection Mold making machines list

| No. | Type | Brand | Set | Maximum manufacturing size | Year |

|---|---|---|---|---|---|

| 01 | 3 Axis CNC | Brother (TAIWAN) | 20 | 1300mmL*1000mmW*500mmH | 2014 |

| 02 | 4 Axis CNC | HASS (USA) | 5 | 1000mmL*1000mmW*500mmH | 2015 |

| 03 | 5 Axis CNC | Brother (TAIWAN) | 3 | 800mmL*800mmW*400mmH | 2015 |

| 04 | CNC Lath | BAOJI (China) | 10 | 400mm Diameter | 2015 |

| 05 | Granding machine | China | 2 | Water cooler system | 2013 |

| 06 | 50A EDM | China | 4 | 50A | 2012 |

| 07 | Wire cutting machine (WEDM) | DCE | 4 | Tolerance range 0.02mm (1100mmLx750mmW working platform) | 2013 |

| 08 | Slow speed Wire cutting machine (WEDM) | Sodick | 1 | Tolerance range 0.002mm | 2013 |

Plastic injection machine with Robot collection system

| No. | Sets | Model | Brand | Cabability (Maxim products size & injection weight) | Year |

|---|---|---|---|---|---|

| 01 | 2 | 800T | JETMASTER (Hongkong) | 800mmLx800mmWx550mmH or weight 1200g | 2014 |

| 02 | 4 | 450 T | JETMASTER (Hongkong) | 500mmLx500mmwx400mmH or weight 800g | 2013 |

| 03 | 12 | 260 T | JSW (Japan) | 350mmLX350mmLx300mmHor weight 450g | 2015 |

| 04 | 6 | HTF160J/TJ | HT (Haitan) | 240mmLx240mmLx250mmL or weight 260g | 2015 |

Project Service Guide

-

Enquiry

Design Source Files(STL、STP etc); Order Quantity; Tolerance Range; Surface Treatment Requirements; Purpose

-

Project Review & Quote

Sign NDA(non-disclose-aggrement) if need. Project Review By Engineers Follow Up Project all details; Make Quotation for client

-

Biz Terms

Shipping method & documents; Term of Payment; Packaging Details; Delivery Date,etc.

-

Project Execution

Production Plan; Workflow & Process Control; Monitoring in whole procedure. Feedback to Client continually.

-

100% QA before Shipping

All Functions Testing; Surface Testing; Go Through All Project Details; Packing Testing; Testing & QA Report.