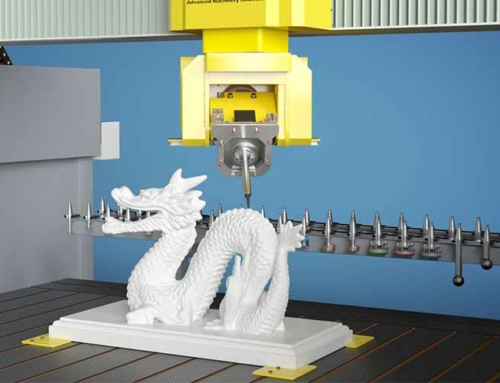

Plastic Injection Molding Suppliers offer Engineering plastic parts in China

First of all, Most of Plastic Injection Molding Suppliers in China offer custom Engineer plastic parts manufacturing services for their customers.These plastic injection molding suppliers will suggest their customers using the best engineering plastic according to the application and design of the part. Therefore, we should have an idea of what is engineering plastic? What is the different character of each commonly engineering plastic?

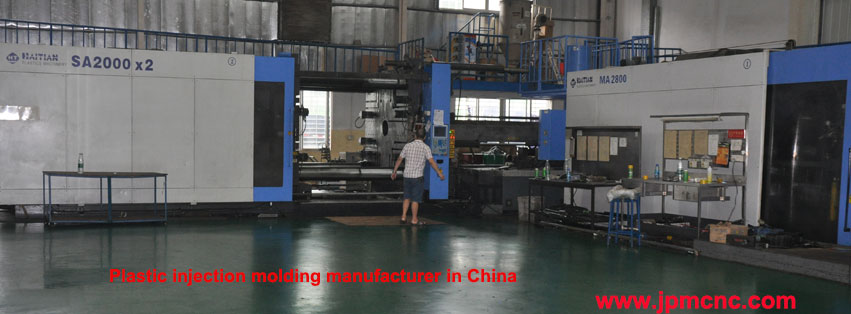

Engineering plastic takes its advantages to be used widely for industry such as Auto parts, House appliance products enclosure, and Medical equipment shell. Comparing with other metal material steel, aluminum, and stainless steel. It is easy to form by injection, extrusion manufacturing process with Low cost and high production efficiency. Here, we JINGXIN as Plastic injection molding suppliers in China would like to share some point of the most popular 6 types engineering plastic below that is used in plastic injection molding suppliers.

Regarding the more details plastic injection molding process of engineer plastic please refer to the links below:

Plastic Injection Molding Suppliers offer Engineering plastic parts in China

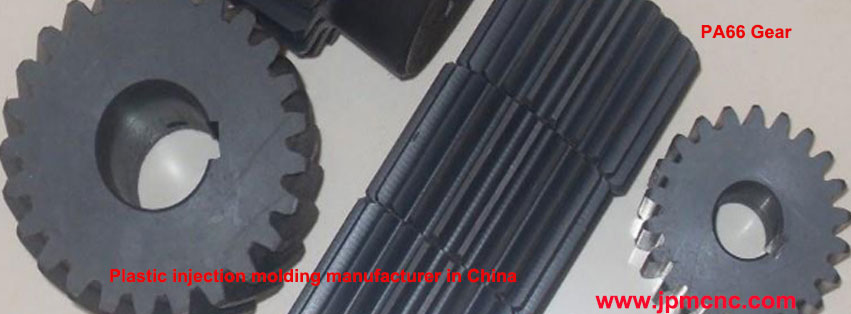

1.Polyamide (PA)

Polyamide, also known as nylon, including nylon 6, nylon 66, nylon 11, nylon 12, aromatic nylon and other varieties, commonly used nylon 6 and nylon 66. They are all raw materials for nylon fibers, but they are also important plastics. Nylon 6 and Nylon 66 are both milky white and translucent crystalline plastics, with heat resistance, abrasion resistance, and excellent oil resistance. However, water absorption is its disadvantage, its mechanical properties vary greatly with the degree of moisture absorption, and the size of the product also changes.

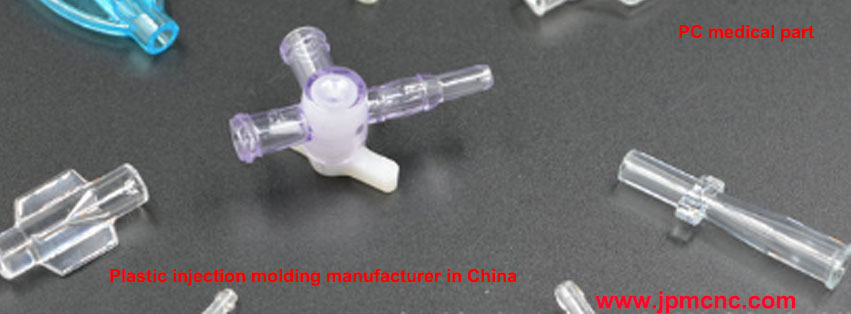

2.Polycarbonate (PC)

Polycarbonate is a transparent, high-strength, heat-resistant plastic. In particular, it has a high impact strength. It also has good creep resistance and maintains its strength even at 120°C. Therefore, it is widely used as industrial plastics. However, the chemical resistance is slightly lower and it is not resistant to alkalis, strong acids, and aromatic hydrocarbons. Polycarbonate is suitable for injection molding, extrusion molding, blow molding and other processing.

Plastic Injection Molding Suppliers offer Engineering plastic parts in China

3.Polyoxymethylene (POM)

POM is a milky-white, opaque plastic with excellent abrasion resistance, resilience, and heat resistance. It is widely used in the manufacture of mechanical parts by injection molding, and it can also be used as a spring. It is a typical engineering plastic.

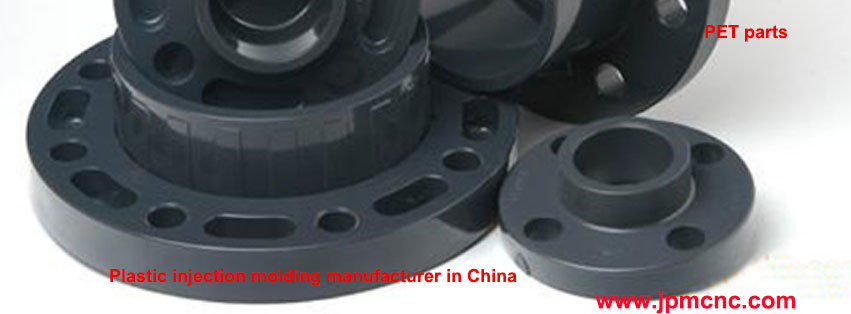

4.Polyester (PET)

The commonly used polyester is polyethylene terephthalate (PET), which is a polycondensation reaction of terephthalic acid and ethylene glycol. And is also a raw material for producing polyester fibers. This polyester has heat resistance and good abrasion resistance, and has a certain strength and excellent air impermeability. Biaxially oriented films made of polyethylene terephthalate are widely used in tapes, movies, and photographic films. Biaxial stretch blow molded bottles are often used as containers for carbonated beverages because they are transparent and carbon dioxide is not easily penetrated.

Plastic Injection Molding Suppliers offer Engineering plastic parts in China

5.Polyphenylene oxide (PPO)

Polyphenylene ether is a high-strength engineering plastic developed in the 1960s. It has the high mechanical strength and creeps resistance, excellent electrical properties, high-temperature resistance at 120°C, and dimensional stability over a wide temperature range. Mechanical and electrical properties change little; moisture absorption is very small, resistant to steam cooking. Widely used in electronics, electrical components, medical equipment, cameras and office appliances.

6.Polysulfone (PSF)

Polysulfone is a thermoplastic high-strength engineering plastic that appeared in the mid-1960s. Polysulfone is characterized by good temperature resistance, excellent dielectric properties, and high dielectric properties in water and moisture or 190°C environments. In addition, radiation resistance is also its advantage. Due to these unique properties, it can be used to make heat-resistant and rigid mechanical parts such as automobiles and airplanes. It can also be used to make precise electrical parts with high heat resistance and stable electrical properties. Such as coil bobbin and potentiometer parts,.etc.

More about plastic injection molding plastic material Characters & Applications please refer to our website: www.jpmcnc.com. JINGXIN is a professional custom plastic injection molding suppliers located in Dongguan China. Welcome to contact us for your injection molding projects.

plastic injection molding china suppliers