The Characters & Applications of most common plastic material used in thermoplastic injection molding

Which kinds of thermoplastic are the best one that will be used for the parts in your design?

What are the different Physical Characters for those most common thermoplastic used in thermoplastic injection molding?

1.Overview of Thermoplastic Injection Molding

Thermoplastic injection molding is the most common way to manufacture parts that are mostly used for the products as supporting or enclosure including industrial and home appliance with its advantage of the low cost and high-efficiency production capability. Thermoplastics are polymers that can be repeatedly molten or softened by heating and solidified by cooling—as a physical change rather than a chemical change that takes place during the creation of thermoset materials. It is important to distinguish what type of thermoplastic should be used for the type of product you want us to help you create. Below are the General Thermoplastic Characters & Applications of most common thermoplastics used in thermoplastic used in injection molding

The most common thermoplastic used in thermoplastic injection molding, Jingxin injection molding manufacturer supplies the insert molding, over molding.

2.General Injection Molding Thermoplastic Characters & Applications

| Abbreviatio | Full name | Density (g/cm) | Shrinkage(%) | Characters | Applications |

| ABS | Acrylonitrile-Butadiene-Styrene | 1~1.2 | 0.5~0.6 | Strong, flexible, low mold shrinkage (tight tolerances), chemical resistance, electroplating capability, naturally opaque, low/medium cost | Automotive (consoles, panels, trim, vents), boxes, gauges, housings, inhalors, toys |

| POM | Polyoxymethylene(Acatal) | 1.4~1.6 | 0.8~2 | Strong, rigid, excellent fatigue resistance, excellent creep resistance, chemical resistance, moisture resistance, naturally opaque white, low/medium cost | Bearings, cams, gears, handles, plumbing components, rollers, rotors, slide guides, valves |

| PC | Polycarbonate | 1.2~1.5 | 0.4~0.7 | Very tough, temperature resistance, dimensional stability, transparent, high cost | Automotive (panels, lenses, consoles), bottles, containers, housings, light covers, reflectors, safety helmets and shields |

| PEI | Polyether-Imide | 1.3~1.5 | 0.5~0.7 | Heat resistance, flame resistance, transparent (amber color) | Electrical components (connectors, boards, switches), covers, sheilds, surgical tools |

| PMMA | Polymethy-Methacrylate(Acrylie) | 1.1~1.2 | 0.4~0.8 | Rigid, brittle, scratch resistant, transparent, optical clarity, low/medium cost | Display stands, knobs, lenses, light housings, panels, reflectors, signs, shelves, trays |

| PES | Polyether Sulphone | 1.3-1.5 | 0.2~0.7 | Tough, very high chemical resistance, clear, very high cost | Valves |

| PS | Polystyrene | 1.0~1.1 | 0.4~0.7 | Very tough, temperature resistance, dimensional stability, transparent, high cost | Automotive (panels, lenses, consoles), bottles, containers, housings, light covers, reflectors, safety helmets and shields |

| HDPE | High density Polyethylene | 0.93~0.97 | 1.2~2.2 | Tough and stiff, excellent chemical resistance, natural waxy appearance, low cost | Chair seats, housings, covers, and containers |

| LDPE | Low density Polyethylene | 0.91~0.93 | 1.5~3 | Lightweight, tough and flexible, excellent chemical resistance, natural waxy appearance, low cost | Kitchenware, housings, covers, and containers |

| PPO | Polyphenylene Oxide | 0.9~0.92 | 1.5~5 | Tough, heat resistance, flame resistance, dimensional stability, low water absorption, electroplating capability, high cost | Automotive (housings, panels), electrical components, housings, plumbing components |

| PA66 | Polyamide(Nylon 66) | 1.1~1.4 | 1~2.2 | High strength, fatigue resistance, chemical resistance, low creep, low friction, almost opaque/white, medium/high cost | Handles, levers, small housings, zip ties |

| PA6 | Polyamide 6 (Nylon) | 1.1~1.4 | 0.8~2.1 | High strength, fatigue resistance, chemical resistance, low creep, low friction, almost opaque/white, medium/high cost | Bearings, bushings, gears, rollers, wheels |

| PA11+12 | Polyamide 11+12 (Nylon) | 1.1~1.4 | 0.8~2.1 | High strength, fatigue resistance, chemical resistance, low creep, low friction, almost opaque to clear, very high cost | Air filters, eyeglass frames, safety masks |

| PBT | Polybutylene-Terephthalate | 1.3~1.6 | 1.5~2 | Rigid, heat resistance, chemical resistance, medium/high cost | Automotive (filters, handles, pumps), bearings, cams, electrical components (connectors, sensors), gears, housings, rollers, switches, valves |

| PEEK | Polyether-Ether-Ketone | 1.3~1.4 | 0.1~1.4 | Strong, thermal stability, chemical resistance, abrasion resistance, low moisture absorption | Aircraft components, electrical connectors, pump impellers, seals |

| PET | Polyether-Terephthalate | 1.4~1.7 | 0.2~2 | Rigid, heat resistance, chemical resistance, medium/high cost | Automotive (filters, handles, pumps), bearings, cams, electrical components (connectors, sensors), gears, housings, rollers, switches, valves |

| PP | Polypropylene | 0.9~0.92 | 1~2.5 | Lightweight, heat resistance, high chemical resistance, scratch resistance, natural waxy appearance, tough and stiff, low cost. | Automotive (bumpers, covers, trim), bottles, caps, crates, handles, housings |

| PPS | Polyphenylene-Sulfide | 1.3~1.9 | 0.1~0.5 | Very high strength, heat resistance, brown, very high cost | Bearings, covers, fuel system components, guides, switches, and shields |

| HIPS | Polystyrene – High impact | 1.3 | 0.3~0.7 | Impact strength, rigidity, toughness, dimensional stability, naturally translucent, low cost | Electronic housings, food containers, toys |

| PVC | Polyvinyl Chloride – Plasticised | 1.2 | 0.3~0.7 | Tough, flexible, flame resistance, transparent or opaque, low cost | Electrical insulation, housewares, medical tubing, shoe soles, toys |

| SAN | Styrene Acrylonitrile | 1.2 | 0.3~0.7 | Stiff, brittle, chemical resistance, heat resistance, hydrolytically stable, transparent, low cost | Housewares, knobs, syringes |

| TPE/R | Thermoplastic Elastomer/Rubber | 0.9-0.93 | 0.3-0.9 | Tough, flexible, high cost | Bushings, electrical components, seals, washers |

The most common thermoplastic used in thermoplastic injection molding, Jingxin injection molding manufacturer supplies the insert molding, over molding.

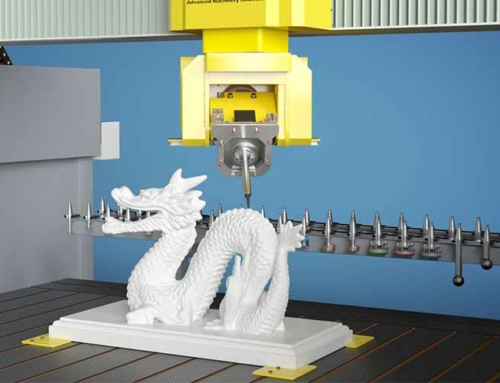

At JINGXIN precision machinery ltd, we’ve specialized in thermoplastic injection molding and mold making in China. Additionally, we’ve expanded into several related areas of custom manufacturing, including custom Rapid machining service, and custom CNC machined parts, reverse engineering.

Having satisfied a vast range of clients across the industrial sector over the past 10+ years, we understand the importance of delivering goods on time and exactly take care about every the customer’s specifications. At JINGXIN, As a custom manufacturing services supplier in China, we reply the customers’questions in hours and quote the enquiring in 12 hours.

Furthermore, our reverse engineering and thermoplastic injection molding service allow us to customize parts for your project at one-site from developing, pre-production to mass production. Visit our website for more information on our capabilities or send us inquiry at email enquiry@jpmcnc.com

More related tips below:

*How to operate injection molding?

*What is plastic injection molding?