Plastic Injection Molding Material Selection Guide

Plastic Injection Molding Material Selection Guide will help you start a new project at the very beginning. As we all know, to make your products outstanding on market with competitive cost is the key factor to be considered for designer or engineer. Therefore, How to choose the suitable manufacturing process? How to choose the right raw material for your part? In this article, firstly we would like to point out why plastic injection molding is the best manufacturing process that is suited for mass production. Secondly, How to choose the plastic injection molding material provided by JINGXIN’s skilled engineers.

The best manufacturing process – Plastic injection molding

Plastic Injection Molding Material Selection Guide

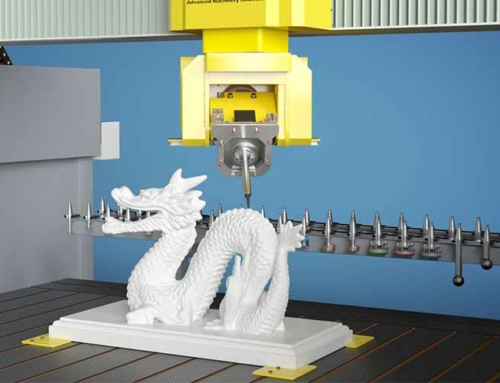

Why we say the plastic injection molding is the best one among others like CNC machining, die casting and newly additive manufacturing.

- All parts in a same size and tolerance all the time

The parts are produced by a design cavity in the mold. Every part has the same tolerance for assembly.

- High production efficiency

Two cavities or more cavities can be designed in a mold.

Every shot in minute

- Competitive cost

Low labor cost. The parts are made by Automatic injection machine with Robot collection system

- Custom finish and color

The molded parts can be customized on the surface finish or color on demand.

- Over-molding for two or more kinds plastic material on single parts

- Rapid tooling for short-run production

Plastic Injection Molding Material Selection Guide: How to choose a plastic injection molding material?

First of all, When you decide to go with plastic injection molding process for your product then there are many properties to think about before starting. So we hope the following tips can help you to guide you to choose the right plastic injection molding material.

1.Application

–Nowadays there are many kinds of thermoplastic that were developed for special use. Therefore, we need to have an overview of the parts application.

- Where were the parts used?

- How long it needs to last?

- What environmental and mechanical conditions will the product be exposed?

- What economic or cost constraints do you have for your product?

2. Plastic Material Character

– To be able to effectively evaluate and select materials it is important to have a general understanding of plastic material characters. Please have a view of the most commonly specified materials in our Thermoplastic Material Guide: the General thermoplastic characters and application. You can use the charts to help you choose a right material for your parts or contact us for an assistance from JINGXIN’S skilled engineer.

3. Select and Test a material

– Once you have a good understanding of the application and material properties you can begin making some sample made of the plastic you expected to test.

4.Specify Plastic Material

– After testing the material, then you can ask a material data sheet from the injection molding manufacturer to check the material data sheet and its performance. As the skilled engineers At JINGXIN injection molding always help guide or suggest our clients a suitable plastic injection molding. Meanwhile, Value added services at JINGXIN is to help our customer on parts design to find the best parts design that is suitable molding process. Also, We JINGXIN provide the cost-effective solutions with right performance.

Learn more about Plastic injection molding

If you have a new project need help, Welcome to contact us:enquiry@jpmcnc.com.