Top 7 main factors that affect custom CNC machining parts cost.

While you had a custom CNC machining parts, Whether you make it at your own working shop or sourcing outside at contracted factory. First of all, how much the cost of custom machined components? Secondly, the designed parts can be machined with effective cost way, easy to machining or not? What is the best material would be used or has a kind of replaceable material with low cost and easy machining? These issues would be settled before going ahead with mass production.

If you want to know exactly the real cost of Custom CNC machining parts, you obviously need to know what influences CNC Machining cost. Then, How to reduce CNC machining parts costs? After all, the reasonable cost and best solutions would help your project finishing in good quality and a short lead time. Therefore, Today JINGXIN as a custom precision CNC machining parts services supplier would like to discuss here the main factors involved in CNC machining parts cost.

No.01. Material selection-The Primary Driver of CNC Machining Parts Cost

As with any type of manufacturing, the material of CNC machined parts you are using affects the manufacturing costs. Some kinds of materials are more difficult to process than others, for example, carbon steel is hard than aluminum alloy. Since steel are processed at a much slower rate than aluminum alloys, even as modern tools and advanced mechanical technology. Some high hardness materials like steel or tungsten carbide can wear away the expensive consumable cutting tools. If you ask the CNC machining services factory to handle potentially hazardous materials that require additional safety precautions, the overall costs may increase significantly. Therefore, even prior to component design. To choose the suitable materials for your CNC machined component is the most important things to be considered.

No.02. Parts’ Dimensions and design;

Of course, The CNC machining Parts’ Dimensions and geometry design are important factors in CNC machining. Obviously, the bigger part, the more material it will need to make it. The more complex the geometric design, the higher the cost of machining. Very tight tolerances are required, long tooling reach, better surface finishing or roughness. These parts that are difficult to form in geometric shapes will cost more than simpler parts. It is surprisingly easy to design components that cannot be manufactured at all or to be extremely expensive when manufacturing.

It is always wise to consult a skilled CNC machining manufacturer during the design phase of the component. This knowledge can help you design a fully functional, highly productive part. At JINGXIN precision machinery limited, our team always provides the custom CNC machining manufacturing solutions with the most effective cost to our customers. if you have parts made by CNC machine. Please send through CAD files to get a project review, to see what our CNC engineering team can help your project.

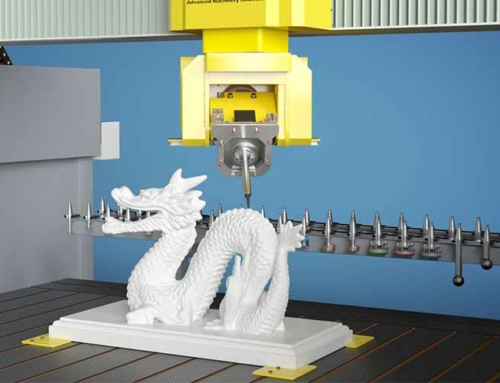

No.03.What kind of CNC machines would be used?

The machine needed to make the part can greatly affect the cost. Can a CNC machining center use a multi-axis machine to complete, or does it require multiple machines? How many different machines and operations are needed? What is size machine needed? Modern processing and manufacturing equipment is very expensive, randomizer types, brand, quality, size And the ability is different. Each of these factors must be considered in determining the exact cost of a CNC machining parts.

No.04. Number of parts to be produced;

One of the most important cost-influencing factors is the Number of parts to be produced. some CNC machining parts require multiple operations and manufacturing process to complete. Each of these operations must be set up and processed. From a basic manual finishing operation, you must put the necessary tools and consumables together to perform very complex machining operations with many tools that can be loaded. They are dialed in, and adjusted to produce the specified tolerances. The operation settings may be completed in minutes, days, or even weeks.

If all the necessary settings are required to run the prototype sample – all relevant costs must be assigned to the sample and it can be very expensive. If you perform the same setup to run 10,000 sheets, you can assign the same setup costs to 10,000 pieces. Which greatly reduces the cost per piece of cost. The frequency of these operations can also play a role. If a customer needs 10+ or 50 pieces parts, it’s cost would be a little bit less than 200 pieces. Therefore, providing a guarantee of the machine’s repetitive work and an accurate estimate. The demand can often be used to reduce the cost of components. So it means for the same custom CNC machined parts, big quantity parts machining cost is much cheaper than low volume order.

No.05.Additional processing

Many CNC machining parts require additional processing such as heat treatment, special processing operations, surface treatments, and specialty coatings. All of these requirements will increase the cost of the basic product and should be evaluated for its necessity and cost that would be involved.

No.06.Experience of machinists;

More complex machined parts require more specialized and skilled machinist. The skills and experience of talented machinists are not without cost Regardless of any formal training program, nothing can replace on-the-job experience and on-the-job training. However, many modern machinists have relevant formal education and on-the-job training. Even if there is a lifetime of processing experience and the industry changes and develops so quickly. The machinist must be a lifelong learner to keep his/her skills at the forefront. The competitive JINGXIN precision machining manufacturer offers continuous training and cross-training opportunities. As the complexity and difficulty of the components increase, the machinist’s experience, and capabilities are also running, so you can see that the cost will increase accordingly.

No.07.Quality requirement & Inspection standards

What kind of tolerance standard is adopted? It is also a cost of the CNC machining parts for CNC machining services factory. High level of inspection and very tighter tolerance would cost higher than lower standard. Therefore, when considering the cost of processing components, it should always give a clear quality requirement for the appropriate level of inspection.

Of cause, there are some other effectors to CNC machined parts cost, such as Material price volatility, local labor cost level, and payment terms.

CNC machine manufacturing involves almost every aspect of modern society since it has many advantages than traditional manufacturing. Production efficiency, the custom CNC machined parts are widely used on construction equipment components and oil & gas equipment parts. It is also used in High precision safety device components, Power generation components, Custom Automotive parts. House appliance products enclosure and Medical equipment shell and components.

Therefore, if you are a designer or sourcing team, JINGXIN precision machining services in China welcome you contact us for your project. If there is anything we can do for you, just send us an email at enquiry@jpmcnc.com, we shall be more than pleased to do so.