Project Description

Prototype Machining

JINGXIN is one of the professional rapid CNC prototype machining services factories in China. The prototype machining process is including rapid CNC prototyping, 3D printing rapid prototyping, silicone vacuum casting, sheet metal stamping, and rapid tooling injection molding. Our prototype machining solutions accelerate product development cycles through concurrent engineering workflows, validating designs for automotive, aerospace, and consumer electronics applications prior to mass production. Trusted by global industry leaders with ±0.01~0.1 mm tolerance, we delivery prototypes in days. A warm service and quick-response sales & R&D team ensure JINGXIN consistently supplies optimal prototyping solutions for industrial manufacturing.

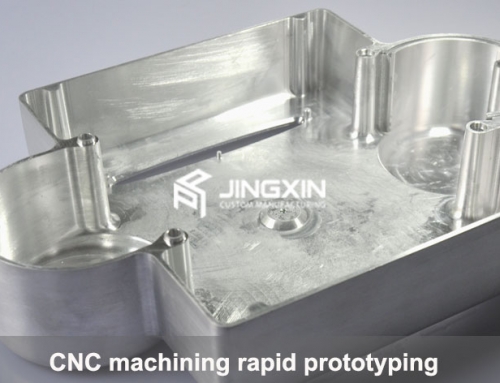

Aluminum prototype machining service

CNC-machined aluminum alloy prototypes

Rapid CNC Prototype Machining Services Factory in China

CNC machined rapid prototypes

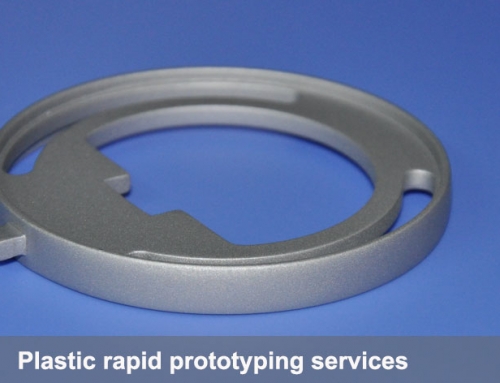

| Project Name | Plastic CNC prototype machining services |

|---|---|

| Application | Medical equipment housing, industrial, auto parts, household appliance |

| Material | ABS, PC, PA, and POM plastics |

| Machinery | 4-axis machines |

| Processes | CNC machining, 3D printing, Rapid tooling, Vacuum casting for short-run production |

| Surface treatment & color | Polish, painting & Plating |

| Part Measurement | Customized on demand |

| Tolerance required | Without marking DIN 2768-M; Special required at ±0.1 mm |

| Packaging | Carton + Wooded Case |

| Quality assurance | ISO 9001:2008, ISO 14001 and BS OHSAS 18001 Certification |

| Document supplied | CMM testing report, ABS Material data sheet & RoHS SGS report |

| Client From | EU |

Prototype machining & Manufacturing process details

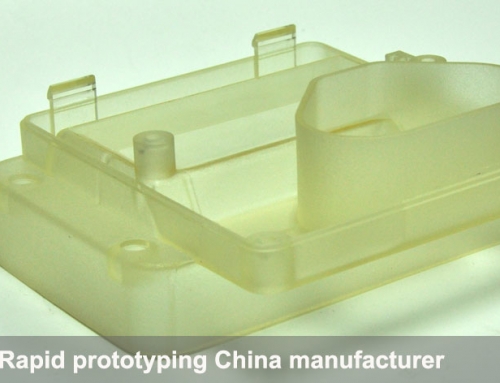

Various raw materials for rapid prototypes are in stock, such as steel, stainless steel, copper, plastic, and aluminum alloys.

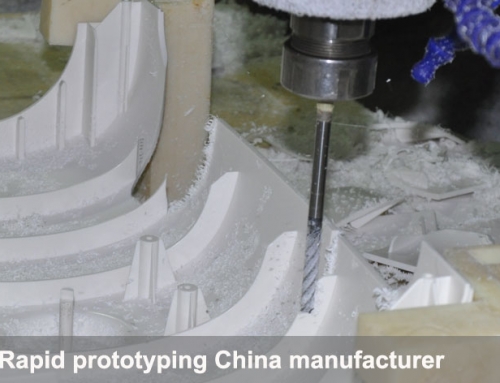

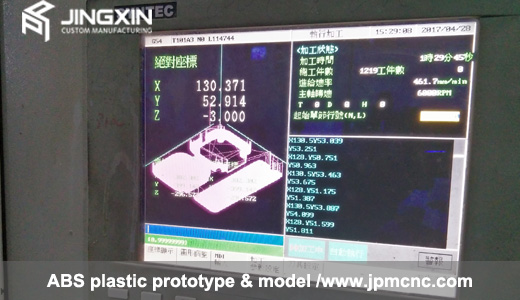

Best and effective manufacturing solutions with perfect CNC machining program

Selecting suitable raw materials for prototypes depends on the prototype’s purpose and customer requirements. Our skilled prototyping engineers makes a production plans based on the prototyping process, including CNC milling, turning, and other processes like laser cutting and EDM, etc.

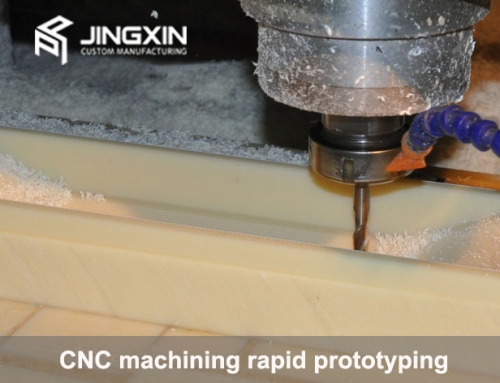

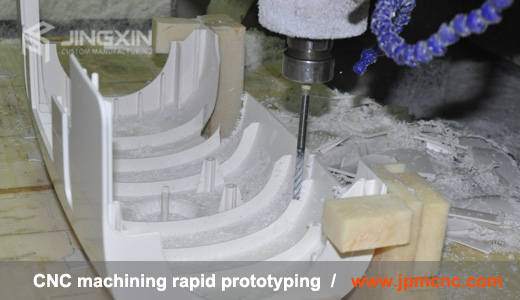

We offer fast CNC milling for plastic prototypes using high-speed CNC machining centers, with deviations ranging from ±0.005 mm to ±0.01 mm.

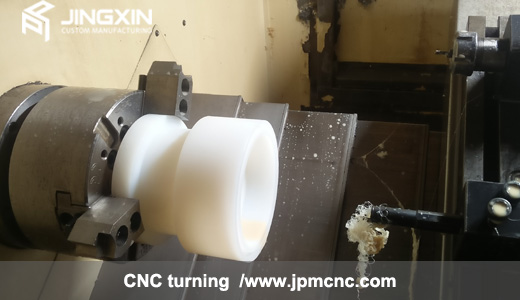

CNC turning rapid plastic prototypes (MOCK-Up)

Fast custom manufacturing with CNC machining centers and lathes. Tolerance range: ±0.02 mm. At JINGXIN, advanced high- performance CNC machining centers enable rapid prototyping, with a machining capacity for workpieces up to 1.5 m × 1.2 m × 0.8 m. SLA printing prototype lead time: 1-3 days; CNC rapid prototype lead time: 3-6 days.

Handmade and surface polishing

Before proceeding with rapid prototype surface treatments like painting or plating, all prototypes are assembled and inspected piece by piece by our machinists after the initial CNC machining process. The surfaces are then hand-polished or machine-polished according to client-specified treatment requirements.

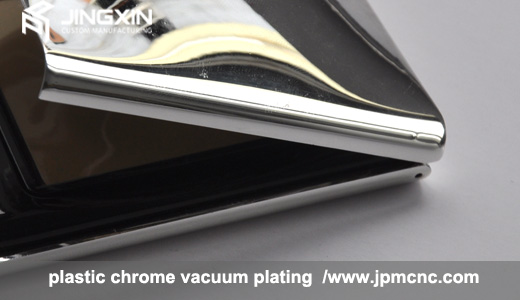

Surface treatment

We perform surface treatments in-house, including spray painting, powder coating, electroplating, and vacuum plating for plastics. For more available finishes for prototypes, please refer to the Finishes page.

Learn more case study

At JINGXIN®, a rapid CNC prototyping company in China, our full range of services includs 3D printing prototypes, injection molding, CNC machining services, rapid manufacturing for short-run production or 10000+ production. Applications include auto parts, medical, industry components. Typical tolerances range from ±0.01 mm to 0.05 mm, with fast lead times of 3-6 working days.