Project Description

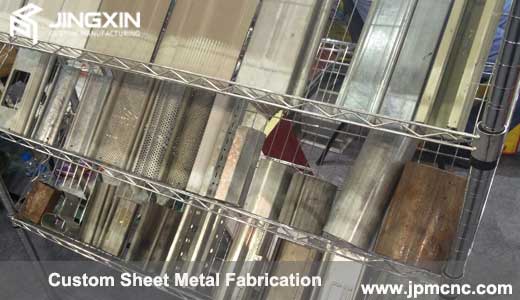

Custom Sheet Metal Fabrication

Custom Sheet Metal Fabrication, Metal bending and Stamping in China

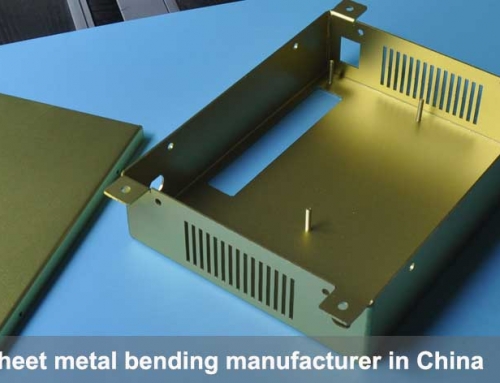

Custom Sheet Metal Fabrication services in China. At JIGNXIN, we offer custom sheet metal fabrication services. The manufacturing process includes sheet metal stamping, deep drawing stamping, CNC bending, water jet cutting, and TIG & MIG welding. Our Custom Sheet Metal Fabrication integrates formability simulation and grain direction optimization to prevent material stress anomalies, delivering structurally sound components for high-vibration environments like industrial robotics and renewable energy systems. Served companies from the USA and EU for 10+ years.

Served companies from USA and EU for 10+ years

The 2000+ projects we have done for our clients from all over the world. Why they choose us as a contracted factory? Because our skilled mold designers take customers’ requirements into consideration during mold design and manufacturing.

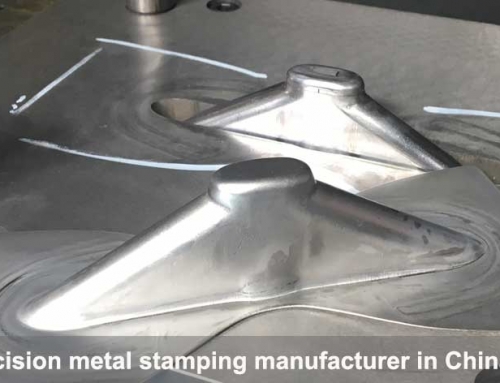

Precision Metal Stamping (Tolerance range: ±0.02 mm)

We understand that our customers need exceptional products that are consistent with quality, design and build specifications. Our company has invested heavily in advanced stamping, bending and deep drawing equipment, enabling us to quickly deliver components in the volumes you need. We have a rapid response team (one sales person and one engineer as a group) in place, whose role is to ensure that your order is completed on time and to provide advice when your design has issues for mass production before mold and tooling making, saving you time and cost for tooling modifications.

Stamping Tooling Designed and Made In-House

All stamping tools and molds are made in-house with our advanced machining equipment. Our 20+ R&D team members each have over 10 years of experience in stainless steel sheet metal fabrication. When receiving new inquiries about custom stainless steel sheet metal parts, we first propose solutions to ensure the newly designed parts comply with stamping process principles while maintaining cost-effectiveness.

To find out more about our services or discuss your project in detail, please contact our Project Manager(Mr. Sammy: sammy@www.jpmcnc.com) directly.

Custom Sheet Metal Fabrication

Custom Sheet Metal Fabrication, Metal bending and stamping in China

| Project Name | Custom metal works |

|---|---|

| Application | Industrial equipment |

| Material | Aluminum, stainless steel, steel |

| Machinery | CNC bending machine, laser cutting, TIG, and MIG welding machines |

| Processes | Sheet metal deep draw stamping process, bending, welding. |

| Surface treatment & color | Polish & plating, painting, powder coating |

| Part Measurement | Customized |

| Tolerance required | Without marking DIN 2768-M; Special required at ±0.1 mm |

| Packaging | Carton + Wooded Case |

| Quality assurance | ISO 9001:2008, ISO 14001 and BS OHSAS 18001 Certification |

| Document supplied | CMM testing report, ABS Material data sheet & RoHS SGS report |

Deep Draw Metal Stamping China Manufacturing Process Details

Custom sheet metal fabrication

Clients provide 3D model designs in STL format. Our engineers convert the STL files into STEP format, then design deep drawing molds according to the product’s design requirements.

Welding and sheet metal fabrication

The mold is manufactured according to the design, completed within 3 weeks through CNC machining, WEDM, EDM, and assembly testing. The first test samples were sent for client confirmation in the fourth week.

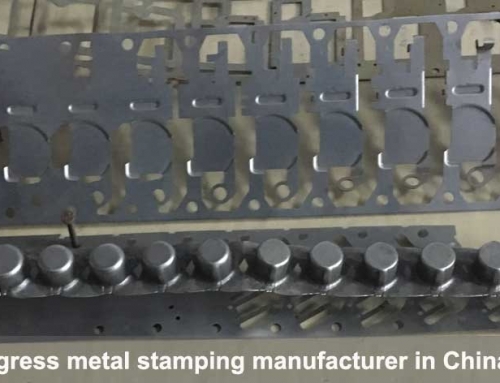

Stamping die & Punching

The sheet metal stamping parts will be completed in 2-3 steps using stamping dies or punching operations with different tooling sets.

progressive-die

Progressive-die tooling is more efficient, saving labor costs and speeding up production while ensuring worker safety.

Thread Tapping

Tapping threads on sheet metal stamping parts, based on part design requirements.

Butt Welding

Some sheet metal stamping parts will be butt welded together according to the client’s design.

Deep draw metal stamping frame

Most metal stamping parts will be completed in 2-3 steps of drawing or stamping using different stamping dies and tooling sets.

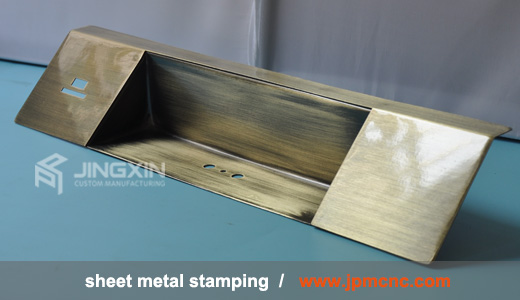

Antique bronze plating finish

At JINGXIN, metal stamping manufacturers supply the parts surface treatment and finish that is painting, plating and powder coating, More available finish that we do in-house please refer to page finishes

Learn more case study

At JINGXIN®, we provide a full range of sheet metal fabrication services including metal stamping, sheet metal bending, deep draw metal stamping, and CNC laser cutting and punching rapid tooling for short-run production or 10,000+ production. Applications include parts for auto parts, medical, industry. The fast lead time is within 3-6 weeks.

To find out more about our services or discuss your project in more detail, welcome to contact our Project Manager(Mr. Sammy: sammy@www.jpmcnc.com) directly for your project.