The difference between shot blasting and sandblasting Pretreatment for CNC Machined aluminum parts

What is a shot blasting process?

Shot blasting is throw small small particles on the surface of the part at high speed

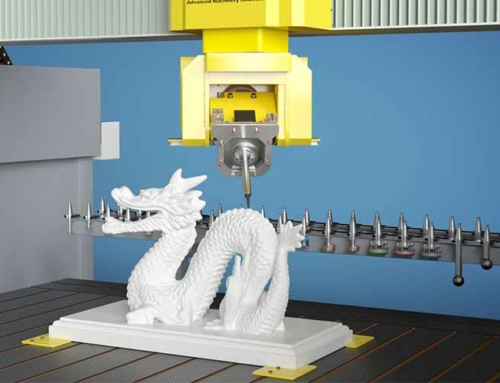

Shot blasting is the use of a high-speed rotating impeller to throw small steel beads or small iron sand onto the surface of the part at high speed. So the oxide layer on the surface of the part can be removed. At the same time, the steel shot or the iron shot hits the surface of the part at high speed. It causes the lattice distortion of the surface of the part to make the surface hardness increase. It is a method for cleaning the surface of the part, the shot blasting is often used to clean the surface of the casting or to strengthen the surface of the part deal with. Generally, shot blasting is used for regular shapes, etc. Several heads are placed up and down together, with high efficiency and low pollution.

Shot blasting is to use the motor to drive the impeller body to rotate.

By the action of centrifugal force, the ball with the diameter of 0.2~3.0 (with casting pill, cutting pill, stainless steel pill, etc.) is thrown to the surface of the workpiece. So that the surface of the workpiece reaches a certain roughness degree. It makes the workpiece beautiful, or change the welding tensile stress of the workpiece to compressive stress, improve the service life of the workpiece. Used in almost all areas of machinery, repairing ships\auto parts\aircraft parts\gun tank surface\bridge\steel structure\glass\steel\pipes\etc. Sandblasting (pill) uses compressed air as a power to spray a diameter of 40 to 120 mesh or a pellet of 0.1 to 2.0 to the surface of the workpiece. It makes the workpiece achieves the same effect. The size of the pellets is different and the treatment effect is different.

The key point is that peening can also play a reinforcing role. Nowadays, domestic equipment has entered a misunderstanding. And it is believed that only shot blasting can achieve the purpose of strengthening. Companies in the United States and Japan use it to intensify and use them! Each has its own advantages. For example, for a workpiece such as a gear, the angle of shot peening cannot be changed. And the initial speed can only be changed by frequency conversion. But it handles a large amount and is fast.

What does sandblasting do?

For CNC machined aluminum parts, Sandblasting is a method of using compressed air to blow out quartz sand at high speed to clean the surface of the part. The factory is also called sand blowing, not only to rust but also to remove oil, which is very useful for painting. Commonly used for surface rust removal of parts; surface modification of parts (the small wet blasting machine sold in the market is this use. The sand is usually steel jade, the medium is water); in the steel structure, the application of high-strength bolts is a comparison The advanced method. Because the high-strength joint uses the friction between the joint surfaces to transmit the force. So the quality of the joint surface is very high, and the joint surface must be treated by sandblasting.

What is the difference between shot blasting and sandblasting?

Repair, shipbuilding, shot blasting, sand blasting are commonly used. But whether it is shot blasting or sandblasting, it is in the form of compressed air. Of course, it is not the impeller that does not use high-speed rotation. In the repair and shipbuilding industry, shot blasting (small steel shot) is often used in steel plate pretreatment (pre-painting rust removal). However sandblasting (repairing and shipbuilding is used in ore) is often used in forming ships or segments.

The role is to remove the old paint and rust on the steel plate and repaint. In the repair and shipbuilding industry, the main role of shot blasting and sandblasting is to increase the adhesion of steel coating paint. In fact, the cleaning of casting parts is not only the use of shot blasting. For large parts, the drum is first cleaned. The riser of the casting is cut off and placed in the drum. The parts collide with each other in the drum, and the sand of the surface is mostly Remove it and then perform shot blasting or shot peening. The size of the shot blasting ball is 1.5mm.

Some study data show shot blasting or sand blasting can improve the fatigue life of the material

Studies have shown that in terms of damage, the tensile stress on the surface of the metal material is much easier than the compressive stress. When the surface is under compressive stress, the fatigue life of the material is greatly improved. Therefore, it is usually sprayed on components such as shafts that are susceptible to fatigue fracture. The pellet forms surface compressive stress and improve product life. In addition, the metal material is very sensitive to stretching, which is why the tensile strength of the material is much lower than the compressive strength. This is also the tensile strength of the metal material (yield, anti-wear). Pull) indicates the reason for the material properties. The working surface of the steel plate of the car we ride every day is reinforced with shot peening, which can significantly improve the fatigue strength of the material.

Machined aluminum parts

At JINGXIN ®, We offer CNC machining services with plastic and metal parts for Short-run production or 10000+ production. Applications include parts for Auto parts, Medical, Industry. Typical tolerance range from +/- 0.01mm-0.05mm; The Fast lead time within3-6 working days.

ISO certificated Factory in China Advanced and high-speed HAAS US brand CNC machines

Skilled R&D Team+Sales Team Manufacturing solution for your projects

Welcome to Contact our Project manager (Mr. Sammy: enquiry@jpmcnc.com) directly for your project.