General description

What is CNC Machine? CNC(Computer Numerical control is a computer numerical control machine and automated-machine used for machining metal parts.

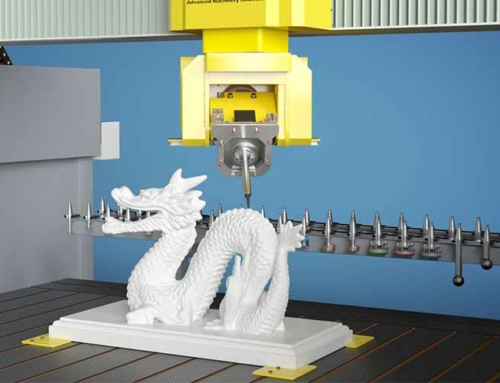

What is CNC machine? You will get a round idea what the CNC machine is after you reading the whole tips. it is a computer numerical control machine and a program-controlled machine used to mill and remove the material from a block to built a part as designed. The use of digital information on the machine movement and processing of the control.

CNC Machine is run by automation and system control

General CNC machining services usually refers to precision machining, CNC machining lathe, CNC machining milling, CNC machining boring and milling machine. The control system can logically process the program with the control code or other symbol instruction. Decode it by the computer so that the machine can perform the prescribed action. And the blank material is processed into semi-finished finished parts by cutting tool. And now CNC machining is widely used in all areas of mechanical processing. Mold processing is the development trend and important and necessary technical means.

CNC Machines can be operated by handshake control handle

What is CNC machine? The traditional mechanical processing is the use of manual operation of ordinary machine work, processing handshake the mechanical cutting tool metal, relying on the eye with a caliper and other tools to measure the accuracy of the product. Modern industry has long been the use of computer digital control of the machine to operate, and CNC machining tools can be prepared in advance by the technical staff of the program automatically on any product and parts directly processed. This is what we say “CNC machining”. CNC machining is widely used in any field of all mechanical processing, mold processing is the development trend and important and necessary technical means.

CNC Machines Operation Blongs to Numerical Control Technology

What is CNC Machine? CNC is a computer numerical control machine and automated-machine used for machining metal or plastic parts and components.

It is the use of digital information on the machine movement and processing of a control method. The machine tools for the implementation of processing control, or equipped with numerical control system machine called CNC (NC) machine. The system including numerical control devices, programmable controllers, spindle drives and feed devices and other parts.

CNC Machine is controlled by some parameters

CNC machine is machine, electricity, liquid, gas, the light height of the integration of products. To achieve the control of the machine. You need to use the geometric information to describe the relative movement between the tool and the workpiece. The use of process information to describe the machine tool must have some of the process parameters. For example feed speed, spindle speed, spindle reversing, tool change, coolant switch and so on. (send those data ( g code) to cnc machine through internet or save on a sd card or disk, perforated tape, tape, etc.), and then read by the CNC system on the machine, by decoding it, so that the machine movement and processing parts.

CNC Machine is advanced integrated manufacturing system tool

Modern CNC machine is a typical mechanical and electrical products and a new generation of production technology with computer integrated manufacturing system. With the development trend of modern technology, CNC machines evolved gradually high-speed, high-precision, high reliability, multi-functional, composite, intelligent and open structure. The main development trend is to develop software and hardware have an open structure of the intelligent full-featured universal numerical control device.

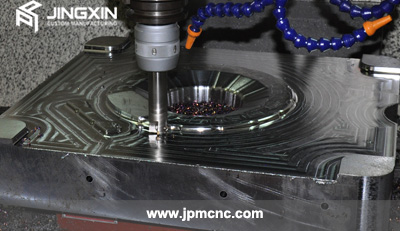

CNC technology is on basic of mechanical processing automation. It integrates the information technology, microelectronics technology, automation technology into detection technology development. Moreover,CNC machining center is an equipment with a live tooling and capability to the workpiece in a certain range of a variety of processing. The parts in the machining center are characterized by the fact that the CNC machining system can control the machine to automatically select and replace the tool according to the different process after one time of clamping. So the machine automatically changes the spindle speed, feed and the relative movement of the tool And other auxiliary functions.

The workpiece on the continuous processing automatically drilling, countersinking, reaming, boring, tapping, milling, and other multi-process processing. As the CNC machining center can focus on the automatic completion of a variety of processes. Not only avoid the man-made operation error, But also reducing the workpiece clamping, measuring and machine tool adjustment time and workpiece turnover, handling, and storage time. This greatly improves the processing efficiency and processing accuracy, So have a good economic benefit.

CNC Machines Types

A machining center according to the spindle in the spatial position can be divided into vertical machining center and horizontal machining center.

Characteristics:

Compared with ordinary machine tools, CNC machining tools have the following characteristics:

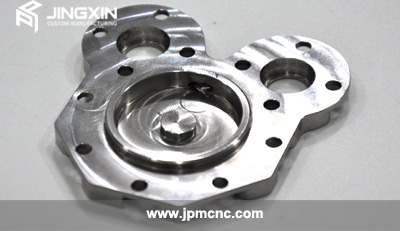

CNC machined S316 stainless steel components

Advantage

- high processing precision, with a high processing quality; +/-0.005-0.01mm

- can be a multi-coordinate linkage, can process the shape of complex parts; by 5 or 6 axis cnc machines

- processing parts change, generally only need to change the NC program, can save production preparation time;

- The machine itself is high precision, high rigidity, can choose the favorable processing amount, high productivity (usually 3 to 5 times the normal machine);

- high degree of automation machine can reduce the labor intensity;

- mass production, easy to control the quality of products;

Disadvantages

- the quality requirements of the operator are low, the technical requirements of the maintenance staff is higher.

- processing route is not easy to control, unlike the ordinary machine as intuitive.

- its maintenance inconvenience, high technical requirements;

- The process is not easy to control.

Professional CNC Machining Manufacturer Provides Precision CNC Process Services

At JINGXIN precision machinery ltd, we’ve specialized in the making of custom CNC machined parts and rapid manufacturer in China. Our CNC machines are HAAS brand imported from the USA. Additionally, we’ve expanded into several related areas of custom manufacturing, including plastic injection molding and mold design, reverser

CNC milling for making plastic injection mold

engineering, rapid prototyping and metal fabrication.Having been satisfied a vast range of clients across the industrial sector over the past 10+ years. We understand the importance of delivering goods on time and exactly take care about every the customer’s specifications. At JINGXIN, we reply the customers’questions in hours and quote the inquiring in 12 hours.

Another extension of our capabilities here at JINGXIN ltd. is our expertise in the various tools and processes of custom manufacturing. From CNC machining services, plastic injection molding, sheet metal forming and rapid prototyping. Furthermore, our reverse engineering and rapid prototyping service allow us to customize parts for your project at one-site from developing, pre-production to mass production. Visit our website for more information on our capabilities or send us inquiry at email enquiry@jpmcnc.com

More tips about CNC machining How does a CNC machine operate?

More Case study about machined parts please refer to our CNC machining service