Project Description

Deep Drawn Sensor Tubes

Deep drawn sensor Tubes, Copper and stainless steel Deep drawn tubes

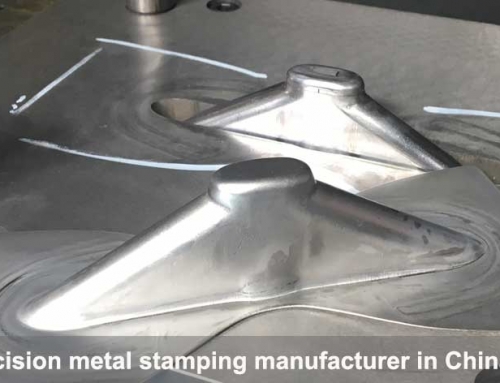

JINGXIN is a Deep Drawn Sensor Tubes Supplier in China. At JINGXIN, we provide custom deep drawn tubes and covers. As a high-precision deep drawing manufacturer, we achieve tolerance of ±0.02 mm with material thickness from 0.1 to 2.0 mm. Our progressive die stamping and deep drawing tooling use high-quality tungsten carbide (Grade YG10). The drawn tubes are applied in medical and electronic products. Metal manufacturing process includes: Sheet Metal stamping, Deep drawing stamping.

Trusted by the most famous companies in the world,

With 2000+ projects completed for clients worldwide, why do they choose us as their contract manufacturer? Our skilled mold designers carefully consider customer requirements during mold design and manufacturing, ensuring precision and reliability.

Precision Metal Stampings (Tolerance range ±0.02mm)

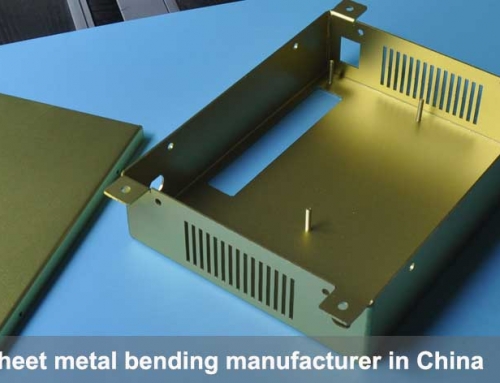

We understand that our customers need exceptional products that are consistent with quality, design and build specification. Our company has invested heavily in advanced stamping, bending, deep drawing equipment, enabling us to quickly deliver components in the volume you need. We have a rapid response team (one sales person and engineer as a group) in place, whose role is to ensure that your order is completed on time and give your our advice in terms of your design has some issues in mass production before mold and tooling making, save you time and cost for tooling modification.

Stamping tooling designed and made in-house

All stamping tooling and mold are made in-house with our advanced machining equipment. Our 20+ R&D team has more than 10 years of experience in stainless steel sheet metal fabrication. First of all, when we receive a new inquiry about custom stainless steel sheet metal parts, we first propose a reasonable solution to ensure the newly designed parts comply with stamping process principles while remaining cost-effective.

To learn more about our services or discuss your project in more detail, please contact our Project Manager(Mr. Sammy: sammy@www.jpmcnc.com) directly.

Deep Drawn Sensor Tubes

Deep drawn sensor tube, Copper and stainless steel deep drawn tubes

| Project Name | Deep drawn sensor tubes , enclosures and covers |

|---|---|

| Application | Electronic products housing, Industrial equipment detectors |

| Material | Aluminum, Stainless steel, Steel, copper |

| Machinery | Precision deep draw metal stamping China machine |

| Processes | Sheet metal deep draw stamping process, Bending, Welding. |

| Surface treatment & color | Polish & plating |

| Part Measurement | Customized |

| Tolerance required | Without marking DIN 2768-M, Special required at ±0.01 mm |

| Packaging | Carton + Wood Case |

| Quality assurance | ISO 9001:2008, ISO 14001 and BS OHSAS 18001 Certification |

| Document supplied | CMM testing report, RoHS SGS report |

Deep Draw Sensor Tubes Metal Stamping in China Manufacturing Process Details

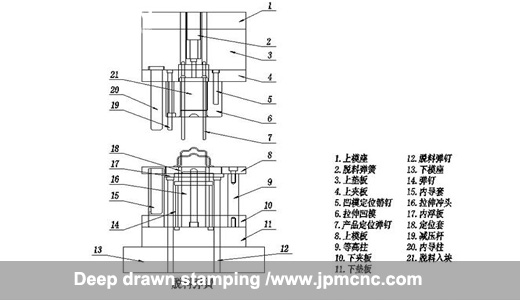

Metal stamping parts tooling design and manufacturing

Clients provide 3D model design with stl format, our engineer converts the stl file into stp format, then design deep drawing mold according to the products design requirement.

Metal stamping parts tooling

Making the mold according to the mold design, the mold finished with 3 weeks by CNC machining, WEDM EDM, Assembly testing, the first testing samples were sent for clients confirmation on the fourth week.

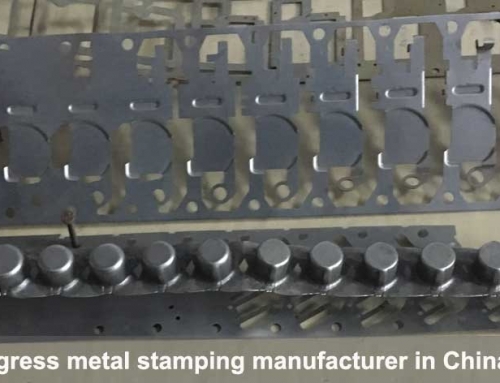

Stamping die & Punching

The sheet metal stamping parts will be finished by 2-3 steps of stamping dies or punchings by different tooling.

Progressive-die

Progressive-die tooling is more efficient in saving labor costs and speeding up production, while ensuring worker safety.

Thread Tapping

Tapping the thread on sheet metal stamping parts up on parts design

Butt Welding

Some sheet metal stamping parts will be butt welded together according to clients’ design

Deep draw metal stamping sensor tube

Stainless steel or copper deep-drawn sensor tubes are widely used in industrial equipment and medical applications.

Anodizing deep drawn aluminum tubes and covers

At JINGXIN, our metal stamping manufacturers supply parts with surface treatment and finishes including painting, plating and powder coating. For more available finishes done in-house, please refer to the Finishes page.

Learn more Case study

At JINGXIN®, we provide a full range of sheet metal fabrication services, including metal stamping, sheet metal bending, deep draw metal stamping, CNC laser cutting and punching, aw well as rapid tooling for short-run production or 10,000+ volume production. Applications include parts for automotive, medical, industry. Fast lead time within 3-6 weeks.

To learn more about our services or discuss your project in detail. Welcome to Contact our Project manager(Mr. Sammy: sammy@www.jpmcnc.com) directly.