Project Description

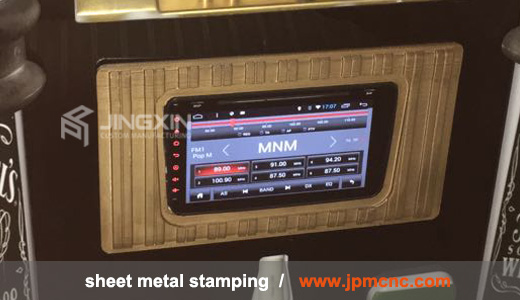

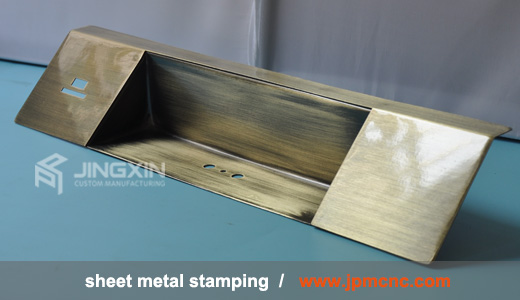

Metal Stamping Companies & Decoration Cover for CD player

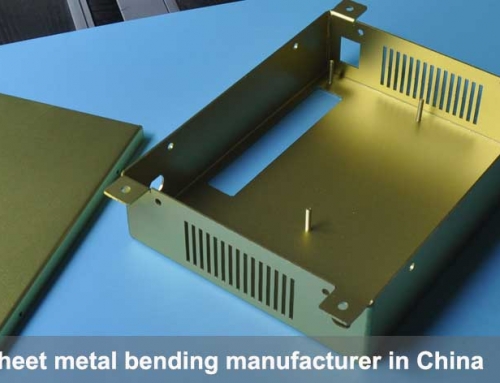

JINGXIN is one of professional sheet metal stamping China companies, the manufacturing process includes sheet Metal stamping, deep drawing stamping, CNC bending. Trusted by the most famous companies in the world, +/-0.1mm tolerance. Our full range of custom manufacturing services includes rapid prototyping, CNC machining, plastic injection molding. JINGXIN is always seeking to supply our best solution to industrial manufacturing.

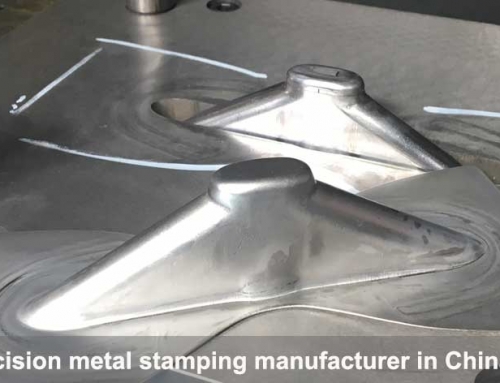

Precision Metal Stampings (Tolerance rate +/-0.02mm)

We understand our customers need exceptional products that consistently meet quality, design and specification requirements. Our company has invested heavily in advanced stamping, bending and deep drawing equipment, enabling us to quickly deliver components in your required volumes. As one of the reliable metal stamping companies in China, we specialize in precision metal components for various industries. We maintain rapid response teams (each consisting of a salesperson and engineer) dedicated to ensuring on-time order completion. These teams also provide design-for-manufacturability feedback before mold and tooling production, helping you avoid costly modifications and save time.

To learn more about our services or discuss your project in detail, welcome to contact our Project Manager (Mr. Sammy: sammy@www.jpmcnc.com) directly.

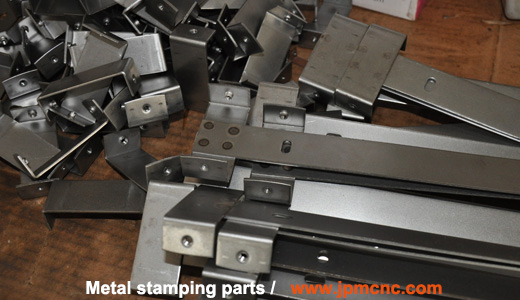

Metal stamping parts

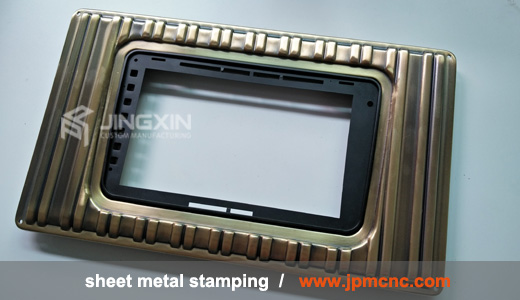

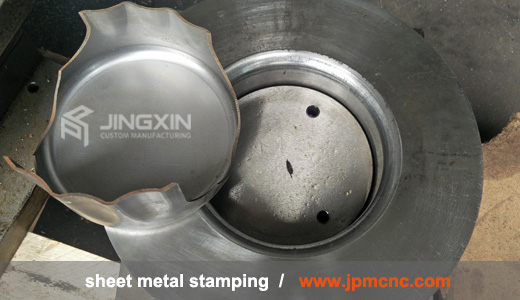

Metal stamping covers for CD player

JINGXIN Metal stamping company

Metal stamping parts details

| Project Name | Decoration CD player cover |

|---|---|

| Application | CD player |

| Material | Aluminum, Stainless steel, Steel |

| Machinery | Sheet metal stamping machine |

| Processes | Sheet metal stamping dies process |

| Surface treatment & color | Polish & Plating, Painting, Powder coating |

| Part measurement | Customized |

| Tolerance required | Without marking DIN 2768-M; Special required at +/-0.1mm |

| Packaging | Carton + Wood Case |

| Quality assurance | ISO 9001:2008, ISO 14001 and BS OHSAS 18001 Certification |

| Document supplied | CMM testing report, ABS Material data sheet & RoHS SGS report |

| Client from | Belgium |

Metal Stamping Parts Manufacturing Process Details

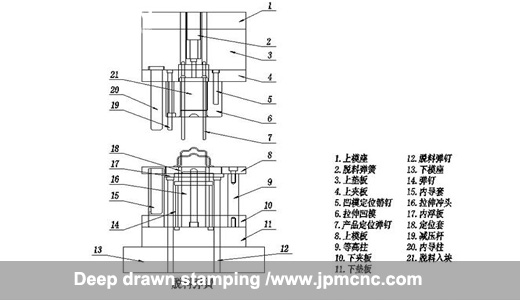

Metal stamping parts tooling design and making

Clients provide a 3D model design in STL format. Our engineers convert the STL file into STEP format, then design the deep-drawing mold based on the product’s design requirements.

Metal stamping parts tooling

Making the mold according to the mold design, the mold finished with 3 weeks by CNC machining, WEDM EDM, Assembly testing, the first testing samples were sent for clients confirmation on the fourth week.

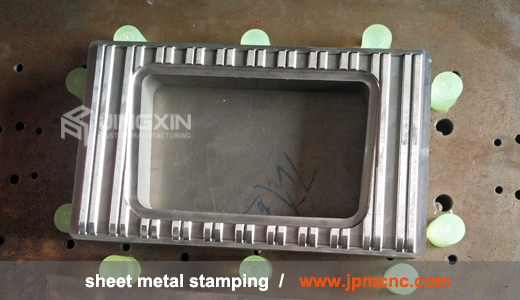

Stamping Die & Punching

The sheet metal stamping parts will be finished by 2-3 steps of stamping dies or punchings by different toolings.

Progressive-die

Progressive-die tooling is more efficient in saving labor costs and speeding up production, while ensuring worker safety.

Thread Tapping

Tapping the thread on sheet metal stamping parts up on parts‘ design

Butt Welding

Some sheet metal stamping parts will be butt welded together according to client’s design.

Metal stamping welded parts

Most of the metal stamping parts will be finished by 2-3 steps drawing or stamping by different stamping dies & toolings.

Antique bronze plating finish

At JINGXIN, metal stamping manufacturers supply the parts with surface treatment and finish including painting, plating and powder coating. For more available finishes that we do in-house, please refer to the “finishes” page.

Learn more case study

JINGXIN® is one of the leading metal stamping companies in China. Our full range of service includes 3D printing prototype, injection molding, CNC machining services and deep drawn parts for short-run production or 10000+ production. Applications include parts for Automotive parts, Medical, Industrial sectors. Typical tolerances range from ±0.01mm to 0.05mm; fast lead time within 3-6 working days.

To learn more about our services or discuss your project in detail, welcome to contact our Project Manager(Mr. Sammy: sammy@www.jpmcnc.com) directly.