Project Description

Precision Automotive Parts CNC Machining

CNC machining parts are widely used in the automotive industry for various applications. Some of the most common automotive components that are manufactured using CNC machining include:

- Engine components: CNC machining is used to create precise engine components such as cylinder heads, engine blocks, and crankshafts. These parts require high precision to ensure optimal performance.

- Suspension components: CNC machining produces suspension components such as control arms, sway bars, and spindles. These parts are critical for maintaining stability and handling of the vehicle.

- Transmission components: CNC machining is used to create transmission components such as gears, shafts, and housings. These parts require high precision to ensure smooth operation and durability.

- Braking system components: CNC machining is used to create braking system components such as brake calipers, rotors, and drums. These parts require high accuracy and precision to ensure safety and performance.

- Interior and exterior components: CNC machining is used to create various interior and exterior components such as door handles, dashboards, and trim pieces. These parts require high precision to ensure a perfect fit and finish.

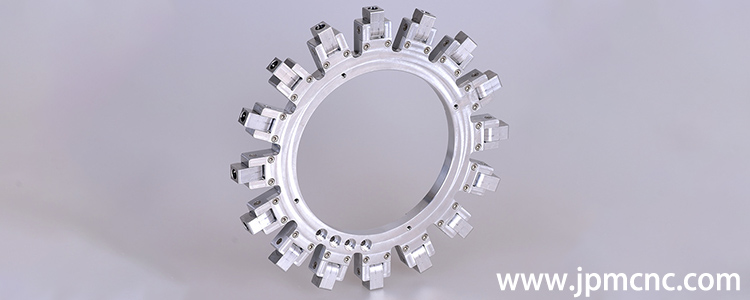

Precision Parts CNC Machining further enhances innovation in automotive manufacturing by enabling the production of complex geometries for lightweight structural parts and advanced sensor housings. This ensures tighter tolerances and material consistency, critical for modern electric and autonomous vehicle systems.

Overall, CNC machining play a critical role in the production of automotive components, helping to ensure that vehicles are safe, reliable, and perform optimally. As a trusted CNC machining service China partner, we ensure end-to-end precision from prototyping to mass production.

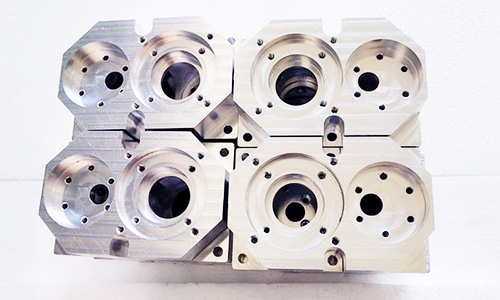

Precision CNC Machining Parts

Custom CNC Machining & Milling Capabilities

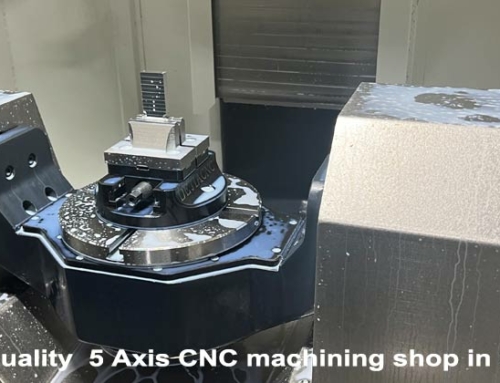

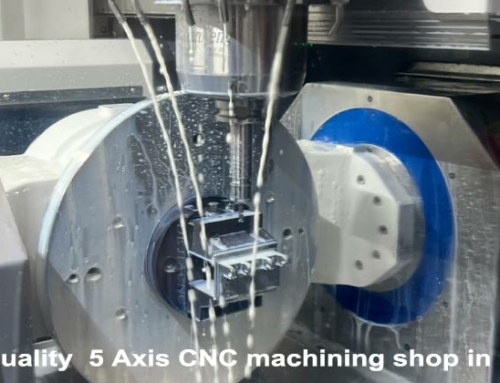

Multi-Axis (4 & 5 Axis) CNC machine center and Vertical Machining Centers (VMC) Maximum machining size

- Maximum Table size 1200mmLx1000mmW

- Spindle speeds up to 12,000 RPM

- Z heights to 508mm

| No. | Model | Brand | sets | Maximum machining parts size | Year |

|---|---|---|---|---|---|

| 01 | 3 Axis CNC machine center | Brother(Taiwan) | 20 | 1200mmL*1000mmW*500mmH | 2014 |

| 02 | 4 Axis CNC machine center | HASS (USA) | 5 | 1000mmL*1000mmW*500mmH | 2015 |

| 03 | 5 Axis CNC machine center | Brother(Taiwan) | 3 | 800mmL*800mmW*400mmH | 2015 |

| 04 | CNC Lath | BAOJI(CHINA) | 10 | 400mm Diameter | 2014 |

Our high precision CNC Milling and turning services are perfect for both one off prototypes and low mass volume production runs. We machined parts from many different plasticn and metal materials on our staste of the art machining finishes available CNC Machining is a very verssatile option. Fast, accurat and competitively priced whilst delivering superior surface finishes from a massive range of material options.

15+ Years’ Experience:

JINGXIN has over 15 years of experience in custom CNC machining services, located in Dongguan City, China. JINGXIN’s professional team adopts reasonable manufacturing solutions and workmanship to supply high-quality one-stop custom CNC machined stainless steel parts.

Focus:

JINGXIN focuses on custom Non-standard CNC precision milling parts such as fittings, valves, hydraulic components, electric motor parts, transmission and pump parts, sprocket wheels, wear parts for packing machines and electronic and medicinal components.

Our Advantage:

- Advanced Equipment: We operate a world-class facility with a variety of precision CNC machines – Brother, Haas, Mazak; vertical milling centers and precision milling and turning lathes, including 3-, 4- and 5-axis models.

- Complete In-House Machining Capability: ISO 2768-F machining standard tolerance, produce parts in a wide variety of sizes and complexities, maximum CNC milling capability up to workpiece diameters from 2–350 mm; Learn more about JINGXIN’s Capability & Services here.

- Raw Material: 100% sure the material complies with RoHS and your requirements, Material certificates and SGS report are available if you need for reference, the various material: steel, aluminum, stainless steel, titanium, engineering plastics such as PEEK, PC, POM, etc.

- ISO-certified Factory Quality Assurance: More details about our testing instruments for precision milling services here.

- Order Quantity: 1+ orders accepted; Short-run precision CNC milling & turning and large-volume production.

- Quick Turn: Quick quotes within hours and fast deliver in days. Skilled and Professional Team (R&D); More about us here.

- Our customers are from the EU and North America. Learn more CNC machining services case study.

What we do to make sure you would get the quality parts from JINGXIN precision CNC milling company:

Advantages Of CNC Machining

CNC machining is great to meet a range of your product development needs. Here are some of the benefits of precision machining:

- Quick removal of large amounts of metal material

- Highly accurate and repeatable

- Suitable for many different kinds of substrates

- Low investment in tooling and preparation costs

- Economical

- Fast turnaround

What we have?

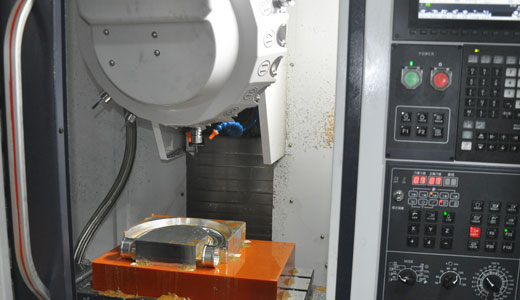

Industry Equipments & Precision CNC machine centers

At JINGXIN CNC machine shop in China, we provide custom high-precision stainless steel parts using world-class CNC machines, including CNC turning and milling centers. This allows us to deliver high-quality, on-demand precision turned components and milled components, with typical tolerances ranging from ±0.002mm to ±0.01mm for metal parts. Please visit our whole factory show for more details about our precision CNC milling equipment.

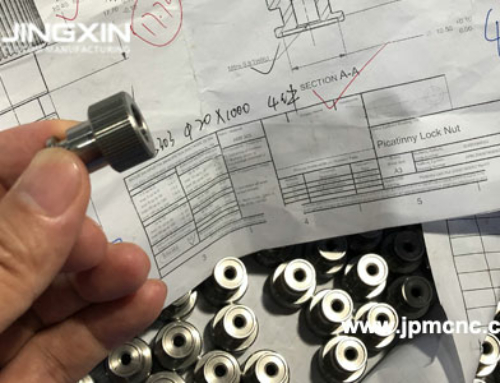

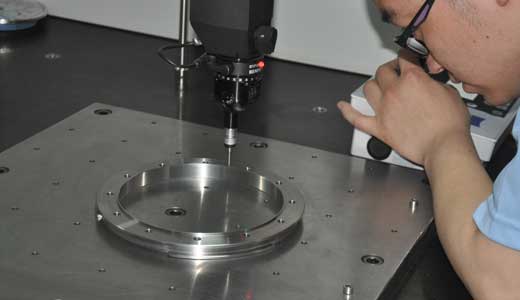

Quality inspection equipments

100% inspection before delivery. Every single size will be checked by the relevant testing instruments: CMM, height gauge, metallurgical microscope, etc. Please see our Quality assurance for more details.

How do we do for precision CNC milling parts?

Precision CNC milling programming

Our skilled engineers optimize the tooling path and propose the best CNC machining process solution according to the design and customer’s requirements. JINGXIN has served worldwide customers for the following parts and so far it is well done: precision-machined 304/316 stainless steel parts, locknut shafts, precision-turned aluminum electric motor parts, precision CNC-milled new energy device components, and precision-turned aluminum components for electronic and medicinal products.

Precision CNC turning workmanship processing

For every single precision CNC-machined part, our team including R&D and production departments will work together to finalize the manufacturing workmanship process. Three key factors ensure the quality:1.The best manufacturing solution & workmanship 2.Optimized tooling path 3.PQC during the whole production, so that JINGXIN can ensure the quality of parts that are what you want from a Precision machined parts supplier in China.

CNC precision milling parts’ finish in-house

We can provide various surface treatments and finishes according to customer requirements for precision-machined metal or plastic parts, including anodizing, black oxide, electroplating, etc. Please see Surface treatment and finish for more details.

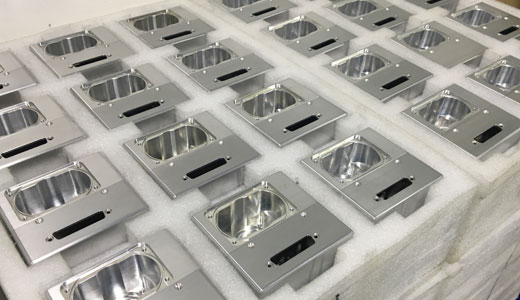

Fast delivery on time & Rush services

1. 1-2 weeks fast lead time and 3-5 days rush services,

2. On-time delivery by worldwide express: UPS, DHL, FedEx, TNT, etc.

3. Proper safe packing: Enhanced carton and wooden case.

How long does it take to get the precision turned parts?

For example: if the order quantity of precision turned components is below 5,000 pcs, then the lead time is 2 weeks, plus shipping time of 2-3 working days, so you will get the parts in less than three weeks. Also, we offer rush service if you need them urgently.

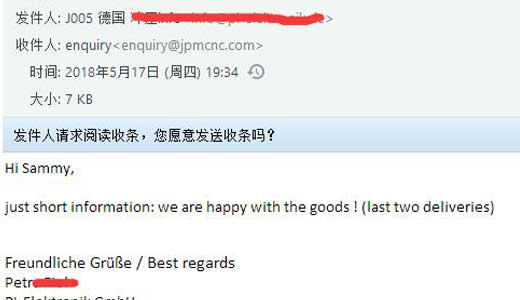

After sale service & Customer feedback

JINGXIN, a precision CNC turned components supplier, has a good reputation for custom manufacturing quality and services: providing precision turned components and CNC milled automotive components such as wear parts for packing machines. Positive feedback has been given to JINGXIN by 99.5% of customers worldwide, including those in Japan, the EU, and the American market.

Project Service Guide

-

Enquiry

Design Source Files(STL、STP etc); Order Quantity; Tolerance Range; Surface Treatment Requirements; Purpose

-

Project Review & Quote

Sign NDA(non-disclose-aggrement) if need. Project Review By Engineers Follow Up Project all details; Make Quotation for client

-

Biz Terms

Shipping method & documents; Term of Payment; Packaging Details; Delivery Date,etc.

-

Project Execution

Production Plan; Workflow & Process Control; Monitoring in whole procedure. Feedback to Client continually.

-

100% QA before Shipping

All Functions Testing; Surface Testing; Go Through All Project Details; Packing Testing; Testing & QA Report.