When foreign structural engineers are looking for some precision machined parts to assembly their machinary and have a good testing, they have been ready for many drawing files for their precision parts machined. That time, they need a qualified parts manufacturer to assist them to process some high precision components to assembly and testing them. But the main trouble the engineers encountered is how to find a qualified custom cnc machining manufacturer,, especially the Right CNC Machining Partner in China.

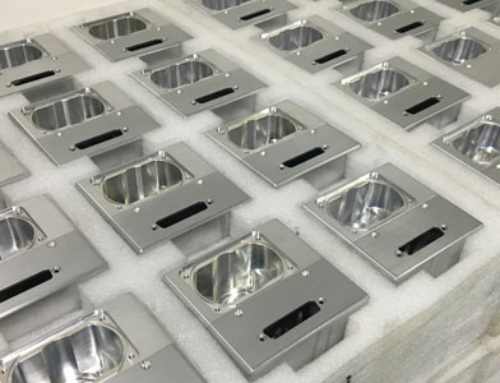

We can produce some high precision machinery parts in regulated time and ensure their project time. So the engineer can look for a few scaled cnc machining manufacturers , and then filter them at last they decide to choose two or three manufacturers to make some samples for them. And deliver these parts to them, and test these parts. Afterwards, the engineer will place some bulk orders to qualified manufacturers. Therefore there a A Comprehensive Guide to Choosing the Right CNC Machining Partner in China.

Comprehensive Guide to Choosing the Right CNC Machining Partner in China

Introduction

As one special foreign engineer or purchase manager, they will consider choosing the right CNC machining partner in China is crucial for ensuring quality, reliability, and cost-effectiveness in your manufacturing processes. This guide covers key considerations, from assessing capabilities to evaluating communication and logistics.

1. Assessing Capabilities

Technical Expertise

- Experience: They need to Look for partners with extensive experience in your industry.

- Certifications: The qualified manufacturers have verify certifications such as ISO 9001, ISO 14001, and industry-specific standards.

- Machinery: Ensure these custom precisoin parts manufacturers have modern CNC machines capable of high precision and complex geometries.

- Materials: Check their expertise in working with the materials you require and capability for process these material (e.g., aluminum, steel, titanium, plastics).

Production Capacity

- Volume: Assess manufacturer production volume, whether it’s low, medium, or high.

- Lead Times: They need know and evaluate their average lead times and flexibility in meeting urgent deadlines.

Quality Control

- Inspection Equipment: These foreign engineer need verify the availability of advanced inspection tools like CMM (Coordinate Measuring Machines).

- Quality Management: They need manufacturers have robust quality control processes, including in-process inspections and final inspections.

2. Evaluating Communication and Responsiveness

Language Proficiency

- Client require their supplier that there is no language barrier. Effective communication in English is crucial for avoiding misunderstandings.

Response Time

- Test their responsive speed by initiating contact and observing how quickly and comprehensively they respond.

Project Management

- They also need manufacturer offer dedicated project managers to streamline communication and handle project coordination.

3. Require some successful cases or portfolios as their refferance

Case Studies and Portfolios

- Show them some case studies and review their portfolio to assess the complexity and quality of their previous work.

Customer References

- Some successful references from past clients, especially those in similar industries or with similar requirements.

Site Visits

- Visit manufacturer’s site to see their operations firsthand and gauge their working environment and capabilities.

4. Analyzing Cost and Value

Cost Breakdown

- Client request a detailed cost breakdown to understand how pricing is structured, including setup costs, material costs, and labor costs.

Value-Added Services

- Provide some value-added design and drawing services, such as design assistance, prototyping, finishing, and assembly.

5. Ensuring Intellectual Property Protection

IP Agreements

- Client request there are clear agreements in place to protect your intellectual property, including non-disclosure agreements (NDAs) and proprietary information agreements.

Legal Environment

- Understand the legal environment in China regarding IP protection and ensure your partner complies with international IP laws.

6. Logistics and Supply Chain Management Needed

Shipping and Handling requirements

- Assess their capabilities in handling shipping logistics, including packaging, labeling, and documentation for international shipments.

Ensure Supply Chain Reliability

- Evaluate their supply chain reliability, including their relationships with material suppliers and their ability to manage supply chain disruptions.

7. Sustainability and Ethical Practices

Environmental Practices

- They require manufacturer to have their commitment to environmental sustainability, such as waste management, energy efficiency, and sustainable sourcing.

Ethical Standards

- Request enterprise implement international labor law rightly, ensure they adhere to ethical labor practices, including fair wages, safe working conditions, and no child labor.

8. Long-term Partnership Potential

Scalability

- Assess their ability to scale with your business as your production needs grow.

Innovation and Adaptability

- They need choose a partner that demonstrates innovation in their processes and adaptability to new technologies and market demands.

Conclusion

Selecting the right CNC machining partner in China requires thorough research and evaluation across multiple criteria. By focusing on technical capabilities, communication, quality control, cost, IP protection, logistics, sustainability, and long-term potential, you can ensure a successful and productive partnership. Conducting due diligence in these areas will help you find a partner that not only meets your current needs but also supports your growth and innovation in the future.

As best custom cnc machining manufacturer in china , JingXin is the Right CNC Machining Partner in China

Custom CNC Machining services Capabilities

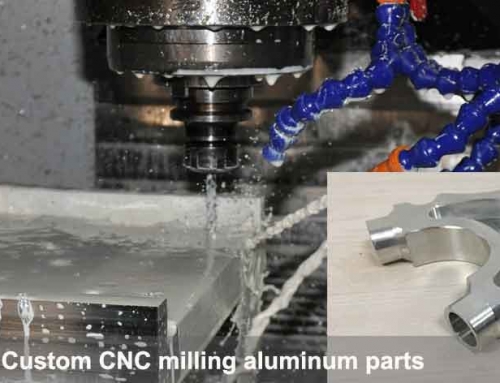

CNC machining service is a manufacturing process where pre-programmed computer software controls the movement of tools and machinery in a factory or workshop. This type of machining is used to create parts or components with high precision and accuracy, and it is commonly used in a variety of industries, including aerospace, automotive, medical devices, electronics, and more.

The application of CNC machining services can vary depending on the industry and the specific needs of the project. Some common applications include:

- Prototyping: CNC machining can be used to create accurate prototypes of a product or component before going into mass production.

- Production: CNC machining can be used for high-volume production runs to produce consistent and high-quality parts or components.

- Customization: By CNC machining, create customized parts or components for specific applications or customer requirements.

- Repairs and Maintenance: CNC machining can be used to repair or replace worn or damaged parts or components.

- Research and Development: CNC machining can be used in research and development to create new products or to improve existing ones.

Overall, CNC machining services are a versatile and widely used manufacturing process that can be applied to a variety of industries and applications.

Multi-Axis (4 & 5 Axis) CNC machine center and Vertical Machining Centers (VMC) Maximum machining size

- Maximum Table size 1200mmLx1000mmW

- Spindle speeds up to 12,000 RPM

- Z heights to 508mm

| No. | Model | Brand | sets | Maximum machining parts size | Year |

|---|---|---|---|---|---|

| 01 | 3 Axis CNC machine center | Brother(Taiwan) | 20 | 1200mmL*1000mmW*500mmH | 2014 |

| 02 | 4Axis CNC machine center | HASS (USA) | 5 | 1000mmL*1000mmW*500mmH | 2015 |

| 03 | 5 Axis CNC machine center | Brother(Taiwan) | 3 | 800mmL*800mmW*400mmH | 2015 |

| 04 | CNC Lath | BAOJI(CHINA) | 10 | 400mm Diameter | 2014 |

Available Material Listing

♦General Purpose material for CNC machining services, Raw material forms can be sheet/bar stick/tubing/plate

♦All materials comply with RoHS (Restriction Of Hazardous Substances), the Material certificate and X-ray inspection report are available.

Non-Metal & Plastics bar /sheet

| No. | Non-metal Material for CNC machining sevices parts |

|---|---|

| 01 | ABS |

| 02 | PC (Polycarbonate) |

| 03 | Delrin |

| 04 | PEEK |

| 05 | POM |

| 06 | PMMA (Acrylic) |

| 07 | Bakelite |

| 08 | PVC |

| 09 | Teflon |

| 10 | Other special plastic |

Metals

| No. | Type | Grade (made in China Or Germany, Japan |

|---|---|---|

| 01 | Aluminum Alloy | EN AW 2007/2017A 5052 /5754/6061/ 6063 / 7075 ,.etc. |

| 02 | Brass&Copper | 3602 / H59 / H62 / C3600/C38500/,.etc. |

| 03 | Stainless steel | SS 301, SS303/SS304,SS316/SS316L/SS400,SS430,etc |

| 04 | Carbon Steel | A2,D2,S136,Q235,GB#20,GB#45.etc |

| 05 | Titanium Alloy | |

| 06 | Magnesium alloy | |

| 07 | Zinc alloy | |

| 08 | Tungsten Carbide | YG8,YG10 |

| 09 | Other | Up on Customer’s requests |

CNC Milling Learn More

A full range services

| CNC Milling | CNC Turning |

|---|---|

| High Speed Drilling | Tapping |

| Boring | Slotting |

| Reaming | Rotary Broaching |

CNC Turning Learn More

Value Added Services

| Lasing cutting service | Laser Marking |

|---|---|

| Welding & Forming for sheet metal fabrication | |

| Debrring to remove all sharp edges and burrs | Assembly & Packaging |

| Product design & assistance | Programming |

- Maximum Table size 1200mmLx1000mmW

- Spindle speeds up to 12,000 RPM

- Z heights to 508mm

| No. | Model | Brand | sets | Maximum machining parts size | Year |

|---|---|---|---|---|---|

| 01 | 3 Axis CNC machine center | Brother(Taiwan) | 20 | 1200mmL*1000mmW*500mmH | 2014 |

| 02 | 4Axis CNC machine center | HASS (USA) | 5 | 1000mmL*1000mmW*500mmH | 2015 |

| 03 | 5 Axis CNC machine center | Brother(Taiwan) | 3 | 800mmL*800mmW*400mmH | 2015 |

| 04 | CNC Lath | BAOJI(CHINA) | 10 | 400mm Diameter | 2014 |

Projects Service Guide

JingXin is the ideal supplier of One-stop Services for Custom Manufacturing Based in China !

Your Content Goes Here