Project Description

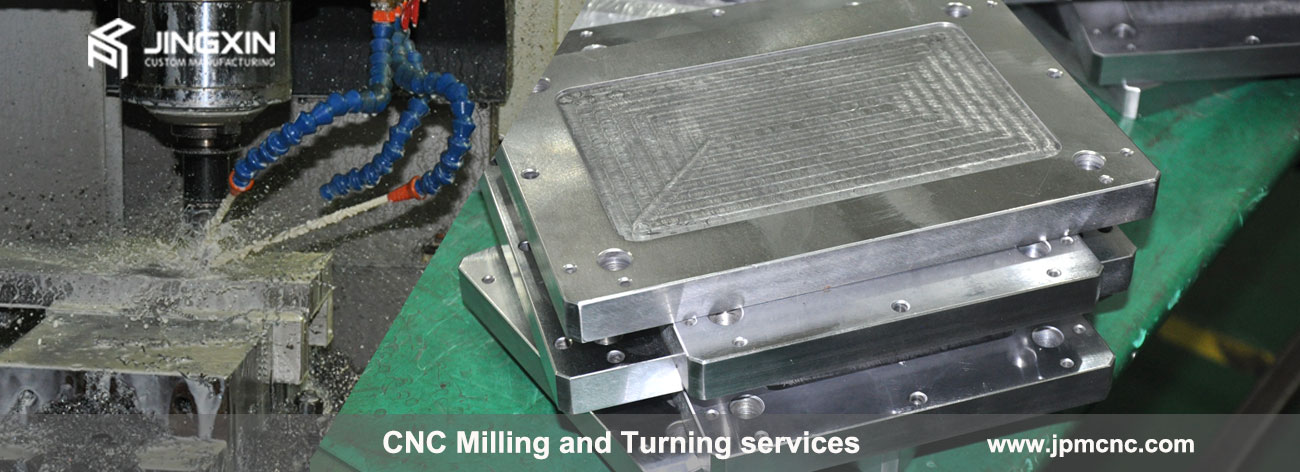

CNC Milling parts (Metal, Engineering plastic)

JINGXIN Precision Machinery Ltd is a professional CNC milling services company in China. Trusted by SCANIA and Volvo Truck Corp in Sweden, JINGXIN has been approved to supply customized high-precision CNC milling parts and CNC turned jigs. We work with various kinds of raw materials, including metal (steel, stainless steel, brass, aluminum) and engineering plastics (PEEK, HDPE, POM, etc.). Surface treatments for CNC milled parts include electroplating, anodizing, painting, and laser engraving. Our CNC milled parts maintain a tolerance of ±0.01mm.

In addition, JINGXIN offers a full range of custom manufacturing services, including CNC milling parts, CNC turning parts, plastic injection molding, and sheet metal stamping. Our CNC machining capabilities cover from prototyping to mass production, ensuring precision and reliability. We are committed to providing the best solutions for industrial manufacturing.

CNC milling parts

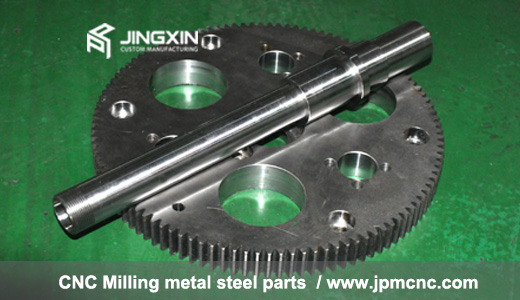

CNC milling parts & Steel gear and axis

CNC milling parts

| Project Name | CNC milling parts |

|---|---|

| Application | Automotive parts, Industrial CNC milling aluminum parts |

| Material | S136 steel, Stainless steel, 6061 Aluminum, Engineering plastic |

| Machinery | CNC Lathe; HAAS 3-Axis Vertical CNC machining center, Wire EDM, Grinding machine |

| Processes | Precision milling, Turning, Laser cutting, Grinding |

| Surface treatment & color | Nitrated & Chemical Black with 72 hours salt spray testing; Hardness HRC 58+/-2, EHT 0.8~1.0mm |

| Part measurement | Customized upon the drawing and clients’ requirements |

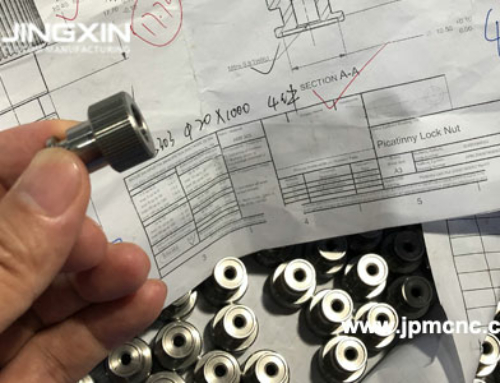

| Tolerance required | Without marking DIN 2768-M; Special required at +/-0.01mm |

| Packaging | Carton + Wood Case |

| Quality assurance | ISO 9001:2008, ISO 14001 and BS OHSAS 18001 Certification |

| Document supplied | CMM testing report, Material data sheet & RoHS SGS report, Salt spray testing |

| Client from | Japan |

JINGXIN’s CNC Machining (Turning and Milling ) Equipment and Capabilities

CNC Lathe turning machining

With world-renowned brand machining centers, JINGXIN provides custom machining services: high-precision CNC turning and CNC milling, speeding up production for its customers.

High precision CNC turning services

it suitable for producing the high precision aluminum ,plastic, and other metal parts with tapping or holes at one site.

CNC milling machine & CNC machining center

CNC milling services, Remove the material from block according to design, High tolerance rate at +/-0.01mm

Surface Treatment & Finish

Case hardened HRC 55-62; surface nitride hardened HRC 58±2, 1mm thickness, with black zinc plating or black oxide finish for metal parts

QC & Height measuring instrument

We offer services including machining parts, surface treatment, plating, painting, anodizing, powder coating, etc.

Rockwell hardness

The parts are required flame hardened at HRC 58 +/-2.

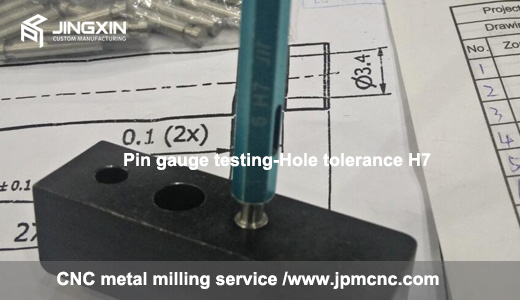

H7 Pin gauge testing for CNC milling componnets

The CNC milled hole diameter is 6 mm with H7 deviation standard to fit the axis or dowel.

Safe packaging to protect CNC milling steel parts

Each custom CNC milling part is protected by foam then put into a wooden box with pallet.

Learn more about CNC machining services and general purpose material for CNC milling services

At JINGXIN®, we offer custom machining China services, including rapid prototyping, SLA 3D printing, CNC milling, and CNC turning for both plastic and metal parts. Our capabilities cover short-run production, one-off CNC machining, and high-volume orders of 10,000+ units. Applications include parts for automotive, medical, electronics, automation, and military industries. Typical tolerances range from ±0.005mm to 0.01mm, with fast lead times of 3–6 working days.