Project Description

Metal Milling Service & SCANIA Automotive Jigs Parts

JINGXIN Precision Machinery Ltd. is a professional metal milling service supplier, specializing in high-performance metal milling services, trusted by Scania Automotive, supplying high-precision CNC machined metal parts for automotive production line jigs, with ±0.01mm tolerance. We offer a full range of custom manufacturing services, including CNC milling, CNC turning, plastic injection molding, and sheet metal stamping. We are always seeking to provide our best solutions to industrial manufacturing.

HRA 58 Hardness SCANIA Automotive Jigs

| Project Name | Automotive Jigs |

|---|---|

| Application | Automotive assembling line |

| Material | S136 steel |

| Machinery | Haas 3-Axis Vertical CNC machining center, Wire EDM, Grinding machine |

| Processes | CNC milling, Turning, Laser cutting, Grinding |

| Surface treatment & color | Nitrated & Chemical Black with 72 hours salt spray testing;Hardness HRC 58+/-2, EHT 0.8~1.0mm |

| Part measurement | 130mm L*90mmW *21mmH |

| Tolerance required | Without marking DIN 2768-M; Special required at +/-0.01mm |

| Packaging | Carton + Wood Case |

| Quality assurance | ISO 9001:2008, ISO 14001 and BS OHSAS 18001 Certification |

| Document supplied | CMM testing report, Material data sheet & RoHS SGS report, Salt spray testing |

| Client from | Sweden |

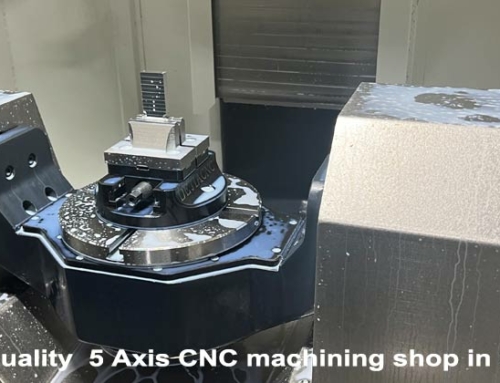

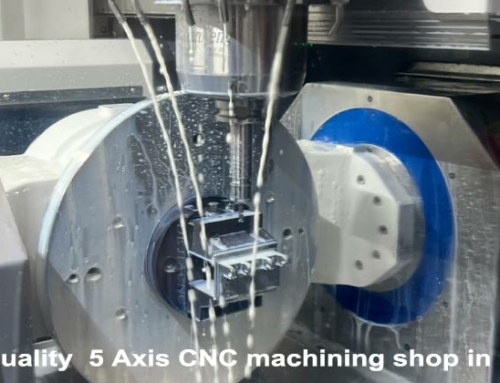

JINGXIN’s CNC Machining Equipment and Capabilities

Haas CNC vertical machining center

With world-renowned brand machining centers, JINGXIN provides custom machining services, delivering high precision and accelerated production for our customers

3-Axis CNC milling machine with live tooling

It is suitable for producing high-precision aluminum, plastic, and other metal parts with tapping or holes in one operation.

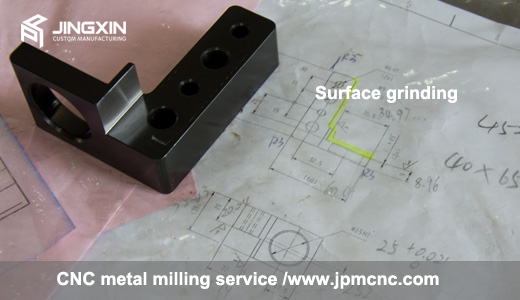

Surface Grinding

The surface grinding machine is used for grinding flat surfaces, and can produce a smooth, accurate finish on either metallic or nonmetallic material with standard Ra 1.6 or 3.2.

Surface Grinding

The surface Grinding machine is used for grinding flat surfaces, can produce a smooth accurate finish on either metallic or nonmetallic material with standard Ra 1.6,3.2

QC & Height measuring instrument

We offer services ranging from machining the parts, surface treatment, plating, painting, anodizing, to powder coating.

Rockwell hardness

The parts are required flame hardened at HRC 58 +/-2.

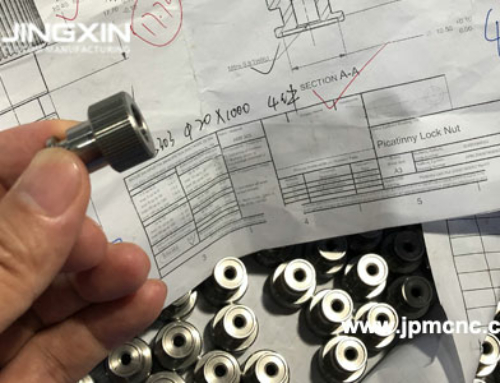

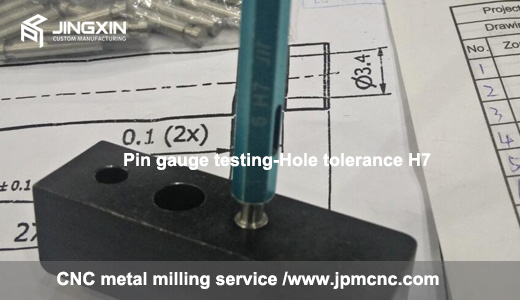

Pin gauge tesing

The hole size is 6 mm with H7 tolerance to match the axis

Safe packaging

Each part is protected by foam then put into a wooden box with pallet

Learn more about JINGXIN’s CNC machining equipment list and general purpose material list.

JINGXIN®, offers custom precision rapid machining services includes rapid prototyping, SLA 3D printing services, CNC milling, and CNC turning, with plastic and metal parts for short-run production or 10000+ production. Applications include parts for automotive, medical, industrial sectors. Typical tolerances range from ±0.01 mm to 0.05 mm; fast lead time within 3-6 working days.