Project Description

Plastic Injection Molding Supplier

JINGXIN is a top-rated custom plastic injection molding supplier in China. Trusted by the most famous companies over the world. Supplying high-quality plastic injection molding parts, the enclosure for electronic products, household appliances, automotive, industrial equipment, ±0.1mm tolerance. Our full range of custom manufacturing services includes CNC machining, CNC milling, CNC turning, plastic injection molding, sheet metal stamping. Plastic Injection Molding Supplier expertise ensures innovative and reliable manufacturing outcomes. JINGXIN is always seeking to supply our best solution to industrial manufacturing.

Food-Grade PP Injection molded plastic parts

Short-run plastic injection molding services

Plastic Injection Molding Supplier

| Project Name | PP plastic handles |

|---|---|

| Application | Electronic products |

| Material | PP -FOOD grade General-Thermoplastic-Characters-and-Applications |

| Machinery | Plastic injection machine |

| Processes | Custom plastic injection molding |

| Surface Treatment & Color | Texture, Matt red 85C |

| Part Measurement | 195mm L*78mmW *35mmH |

| Tolerance Required | Without marking DIN 2768-M; Special required at ±0.1mm |

| Packaging | Carton + Wood Case |

| Quality Assurance | ISO 9001:2008, ISO 14001 and BS OHSAS 18001 Certification |

| Document Supply | CMM testing report, ABS Material data sheet & RoHS SGS report |

| Client From | USA |

| Lead Time | 4-6 weeks for mold making, 3-5 weeks for injection molding production |

China plastic injection molding & Manufacturing process details

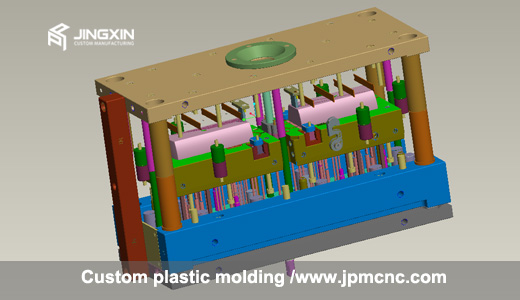

Injection mold design

Clients provide 3D model design in STL format, our engineer converts the STL file into STEP format, then designs the plastic injection mold according to the product’s design requirements, including water cooling, gate type, ejection methods and Moldflow illustration.

Mold making

Making the injection mold according to the mold design, Using LKM mold base and standard mold accessories, the mold finished with 3 weeks by CNC machining, WEDM EDM, Assembly testing, the first testing samples were sent for clients confirmation on the fourth week.

Mold making

Making the mold according to the mold design, using LKM mold base and standard mold accessories. The mold is finished within 3 weeks by CNC machining, WEDM, EDM, and assembly testing. The first testing samples are sent for client confirmation in the fourth week.

Injection molding manufacturers production

The clients confirmed the first samples (T1), gave us some advice and minor changes, then the second mold testing and samples were carried out. Mass production begins after receiving final confirmation from our client and a formal mass production order.

Learn more about plastic injection molding supplier case study

JINGXIN® is a custom manufacturing service factory, offering custom manufacturing service, 3D printing prototype, injection molding, CNC machining services, and metal stamping with plastic and metal parts for short-run production or 10,000+ production. Applications include parts for automotive parts, jigs, medical, industry, household appliances. Typical tolerance range from ±0.01mm to 0.05mm; fast lead time within 3-15 working days.